Installation & Commissioning

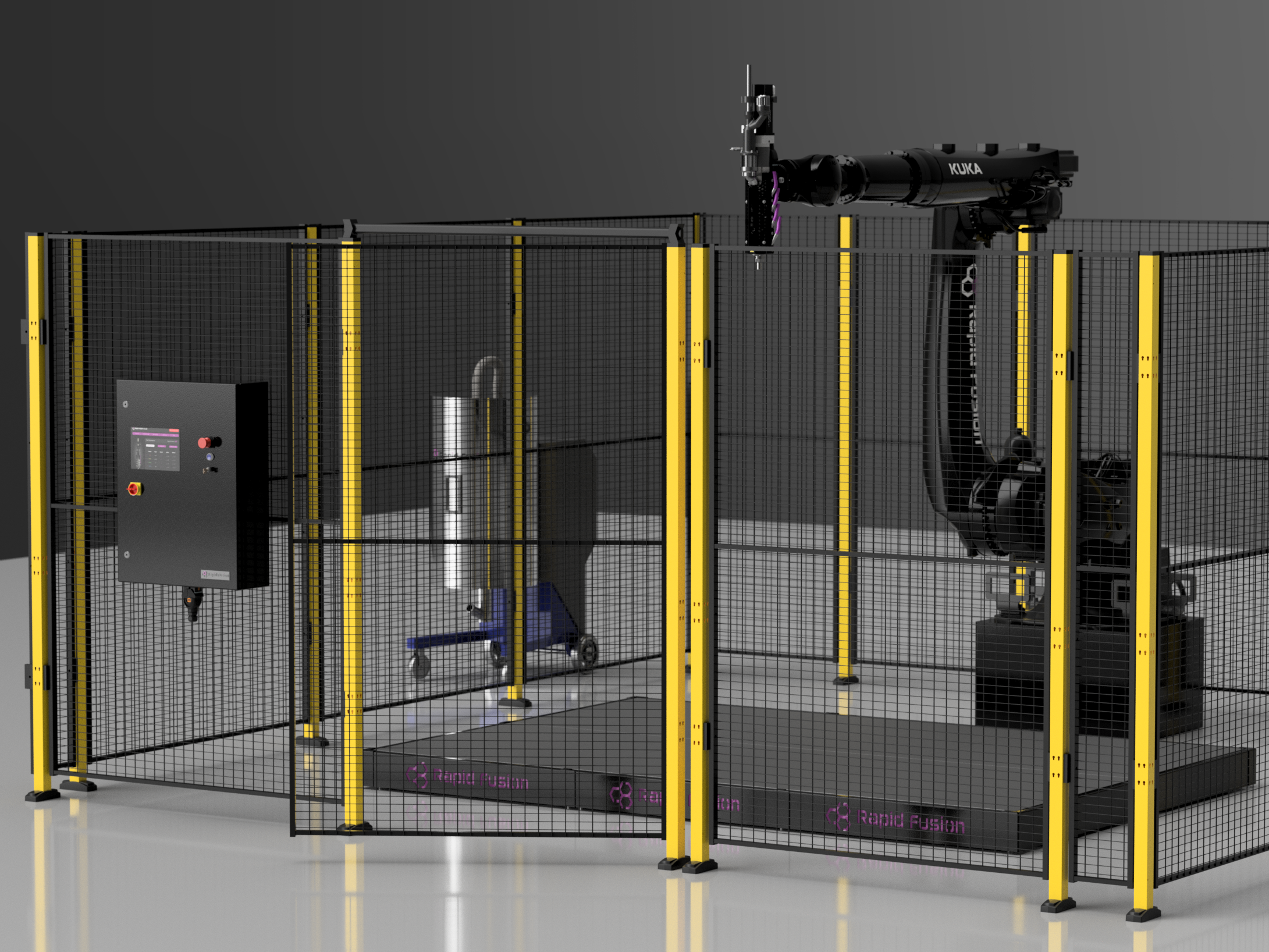

Robotic Hardware:

Supply and delivery of the actual robotic arms and associated hardware. Extruders, pellet feeding systems and any specialised tools required for specific tasks such as rails systems or rotary tables.

Control System:

Provision of the robotic control unit and related hardware components.

Installation and configuration of the control system.

Programming and Software:

Installation of necessary software for programming and controlling the robots.

Programming services to customize the robot's tasks and functionalities in line with specification.

Safety Systems:

Implementation of safety features and systems to comply with industry standards.

Installation of safety cell, sensors and emergency stop mechanisms.

Testing and Commissioning:

Rigorous testing of the entire robotic system to ensure functionality and performance.

Commissioning services to initiate and fine-tune the system for optimal operation, test prints to ensure the system is working correctly.

Rapid Fusion

Applications Support

Application Support represents a collaborative commitment to shared work, encompassing various services such as consultancy in product design for printability or material selection and testing, designing products for additive manufacturing, and developing new functionalities.

These packages are offered in three sizes: 50, 100, and 200 hours and can be used as and when within certain time frames.

Rapid Fusion

Training

Training for robotic arm operation is a program designed to equip operators with the skills and knowledge necessary to proficiently operate robotic arms. Participants in this training gain insights into fundamental principles of robotics, safety protocols, and hands-on experience in programming and controlling robotic arms.

On completion participants will be able to perform:

• Safe program operation

• System startup, Shutdown procedure and error recovery

• Perform program resets.

• Modify Program positions.

• Backup and Restore system information.

Overall, the training ensures that individuals are well-prepared to harness the capabilities of robotic 3D Printing, contributing to enhanced productivity and safety in diverse operational environments.

Rapid Fusion

Certification

Machinery Directive 2006/42/EU

The main legislative framework for the safety of machinery is the Machinery Directive 2006/42/EU, which is the blanket framework for all machinery being placed onto the European product market. Almost all robots would have to adhere to this regulation first and foremost.

ISO 10218-1:2011 specifies requirements and guidelines for the inherent safe design, protective measures and information for use of industrial robots. It describes basic hazards associated with robots and provides requirements to eliminate, or adequately reduce, the risks associated with these hazards.

Service & Maintenance

We offer 3 packages to suit your needs:

Silver Package

- Annual Maintenance Visit

– Screw/Barrel - RTB for warranty Claims (Parts and Labour included)

Gold Package

- Annual Maintenance Visit – Screw/Barrel

- Onsite support for warranty Claims (Parts and Labour

included) - 5 Day turn-around

Platinum Package

- Annual Maintenance Visit – Screw/Barrel

- Onsite for warranty Claims (Parts and Labour included)

- 48Hour Turn-around