Rapid Fusion

Turn-Key Cells

Zeus (Coming soon)

Apollo

ADV Robotic 3D Printing

Artemis (Coming soon)

Apollo

Critical Systems

Extruders

Learn More

Robots

Learn More

Control System

Learn More

Heated Bed

Learn More

Airflow System

Learn More

Cell/ Guarding Options

Learn More

Pellet Drier

Learn More

CAM Software

Learn MoreCertification & Customer Success Plan

Installation

Learn More

Commissioning

Learn More

Training

Learn More

Certification

Learn More

Applications Support

Learn More

Servicing & Maintenance

Learn MoreRapid Fusion

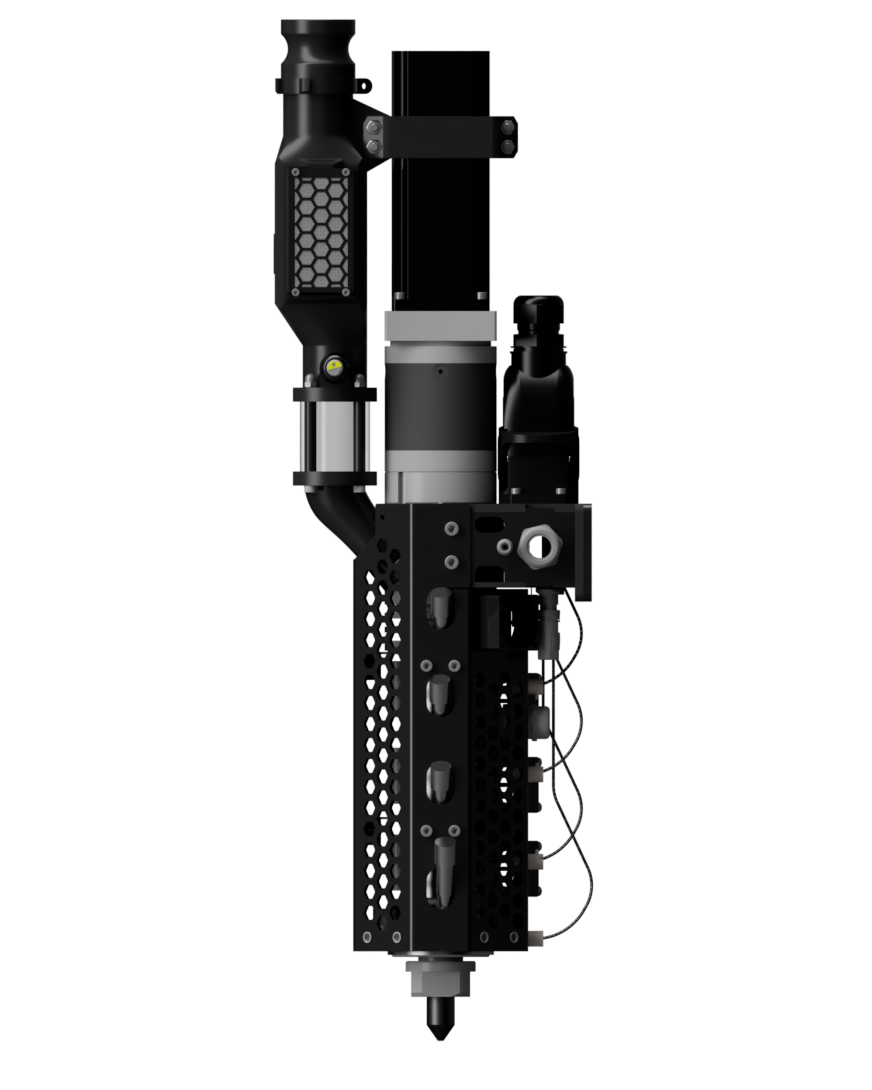

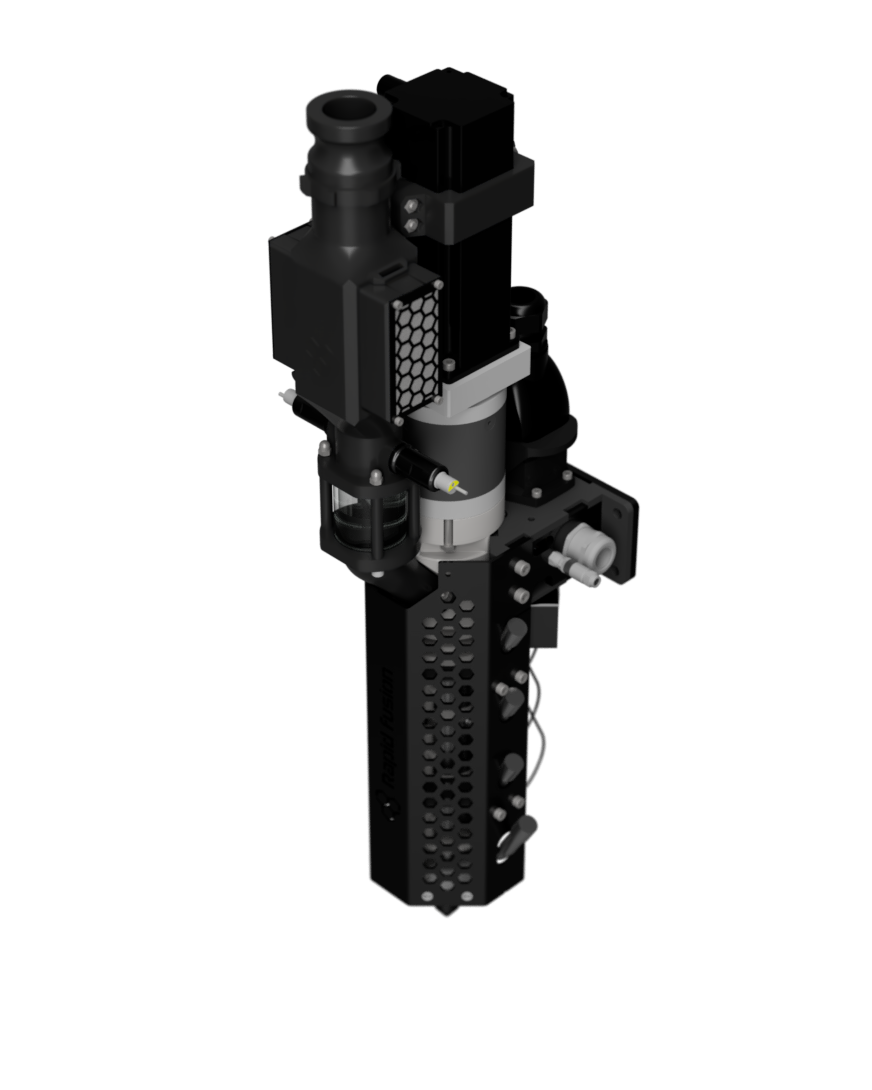

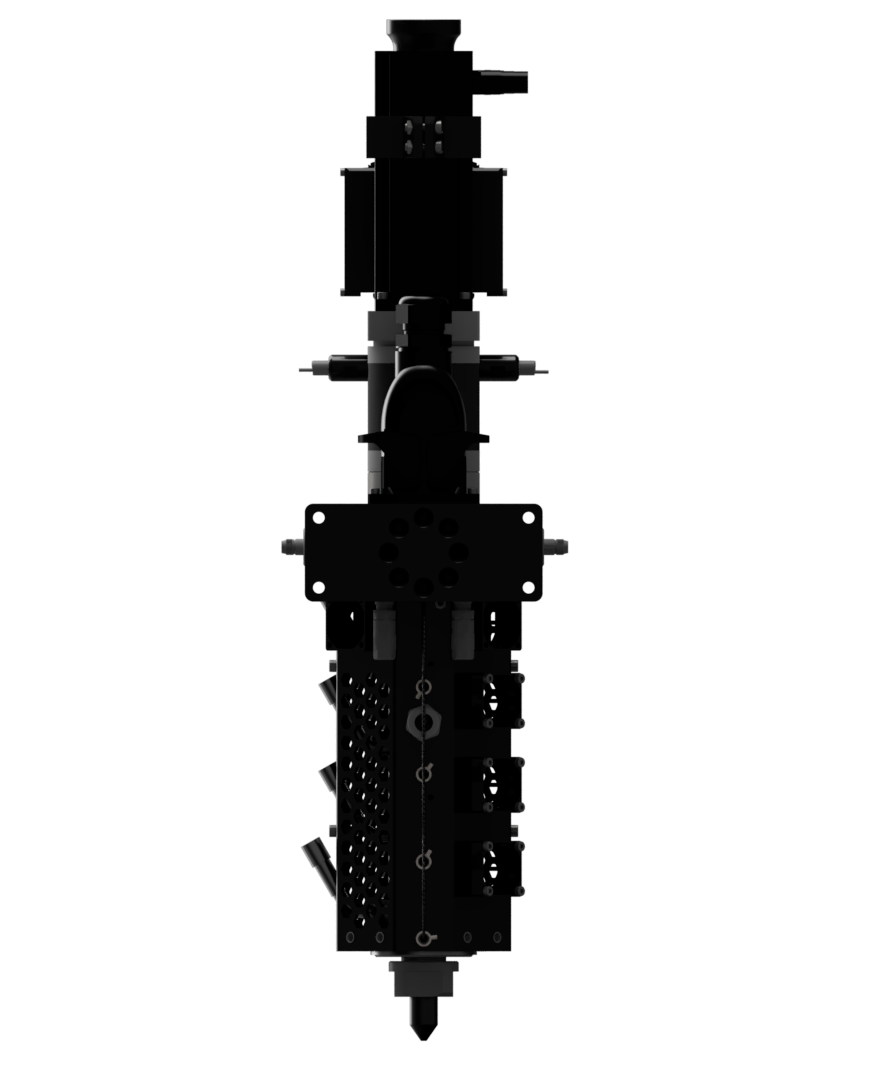

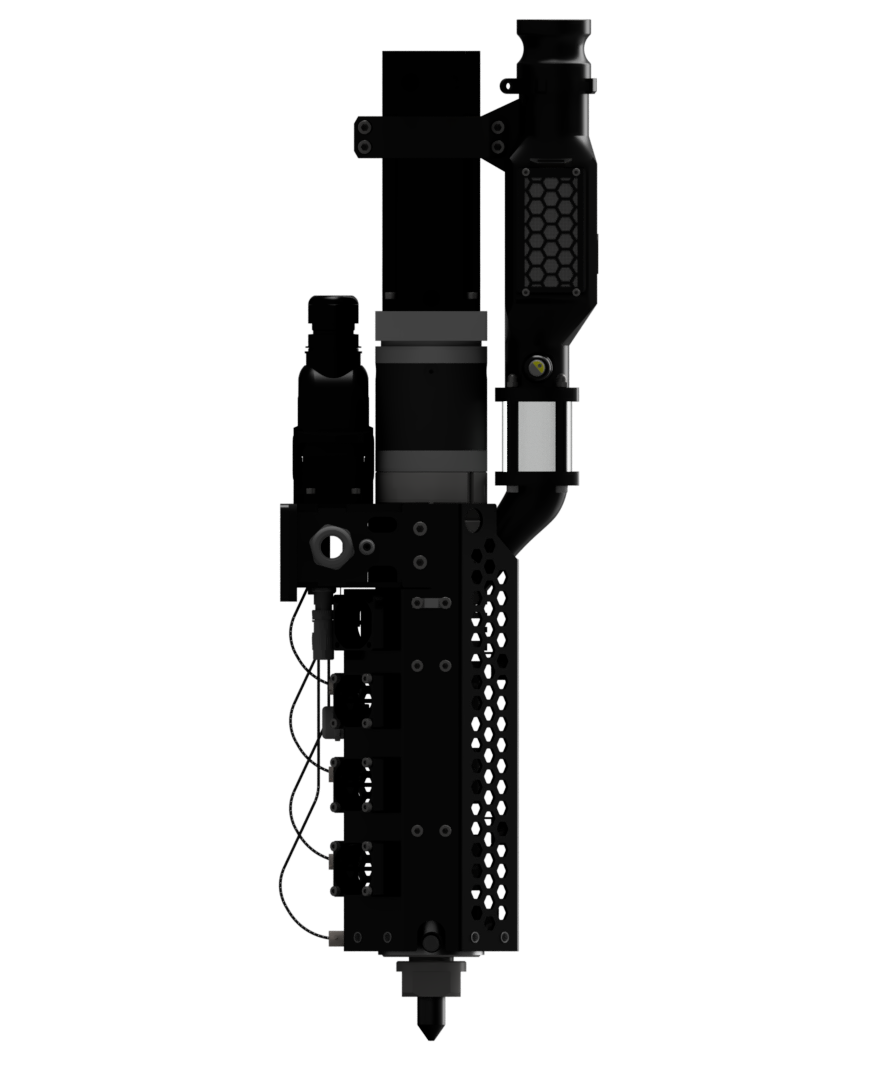

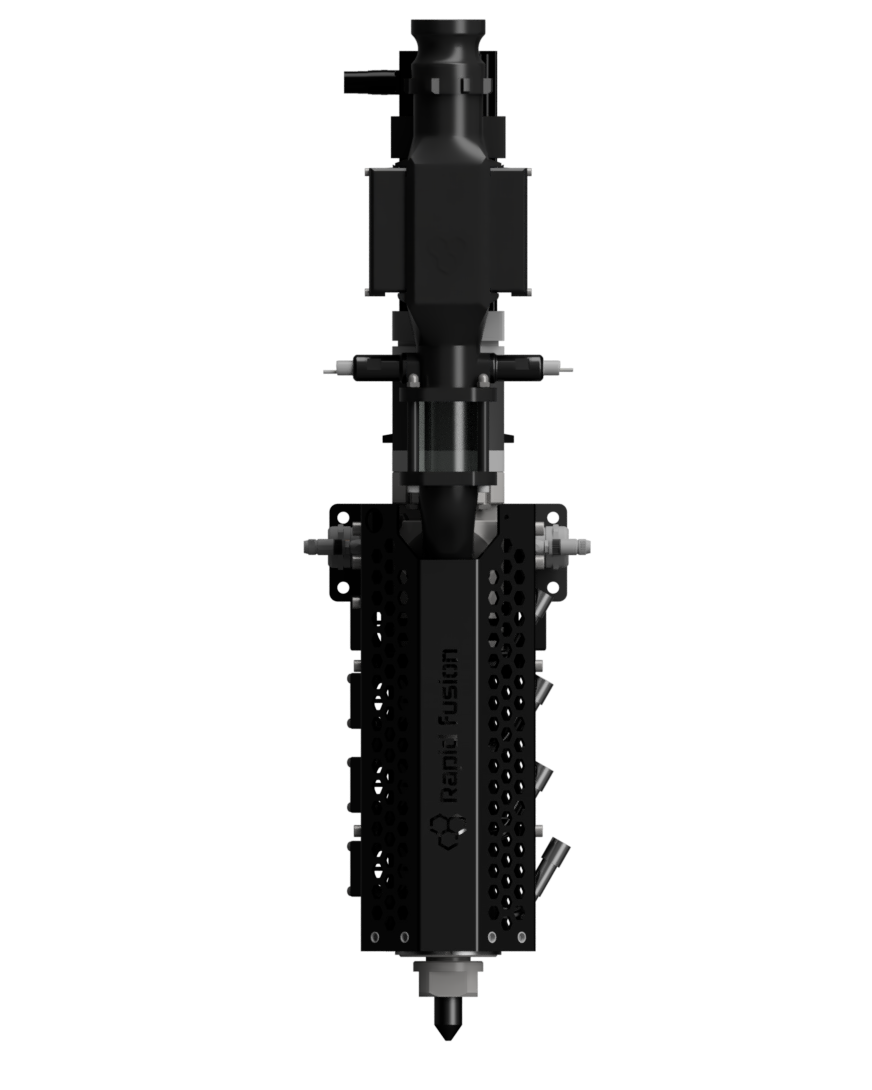

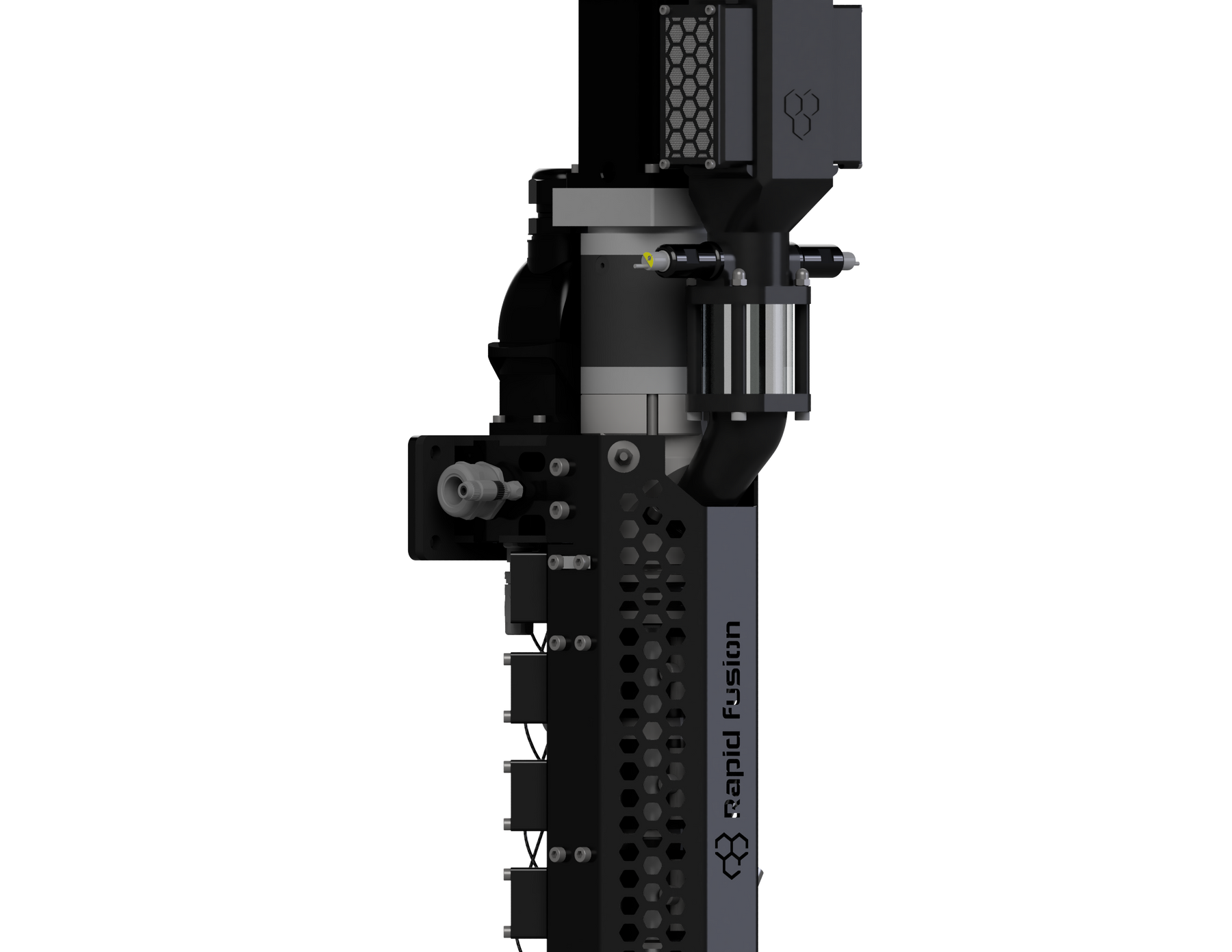

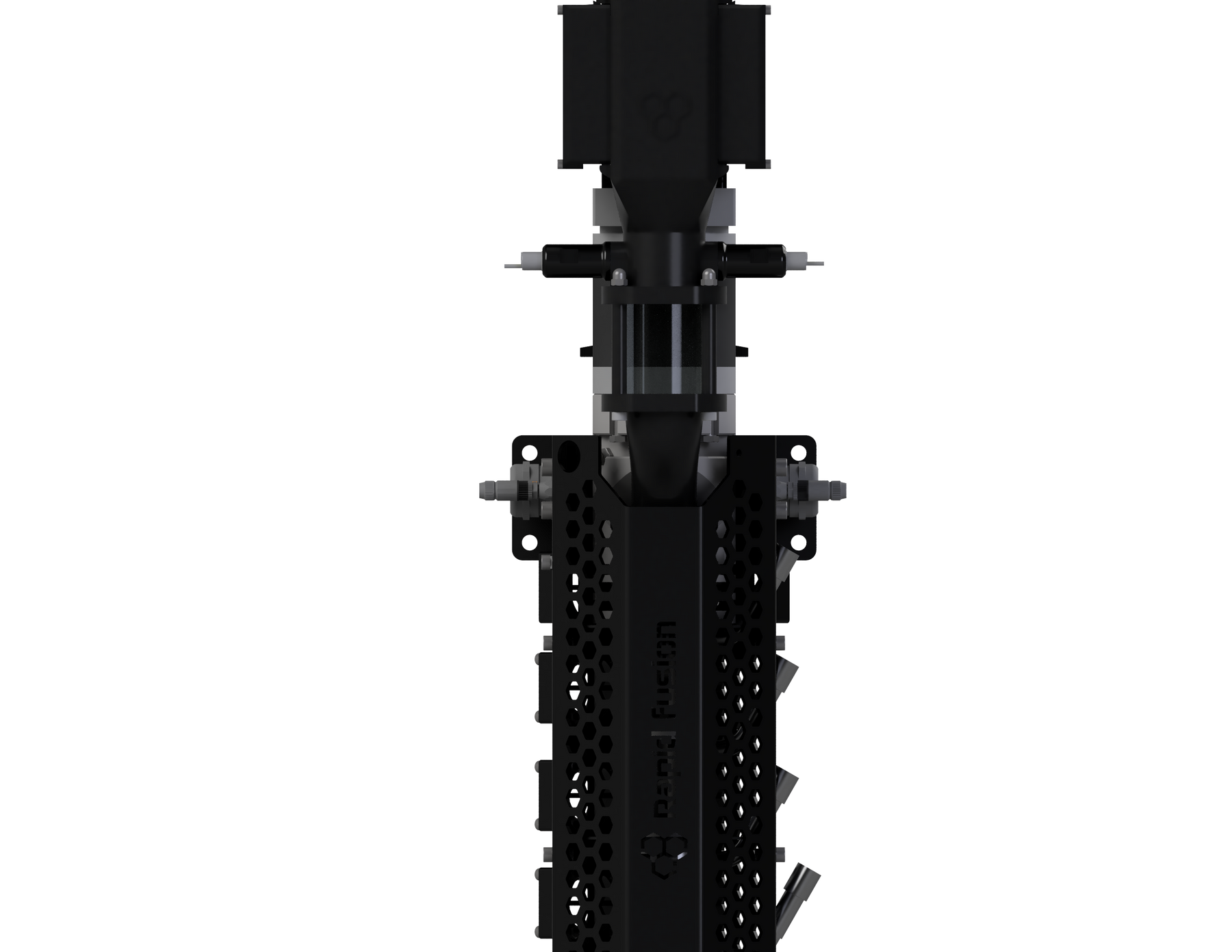

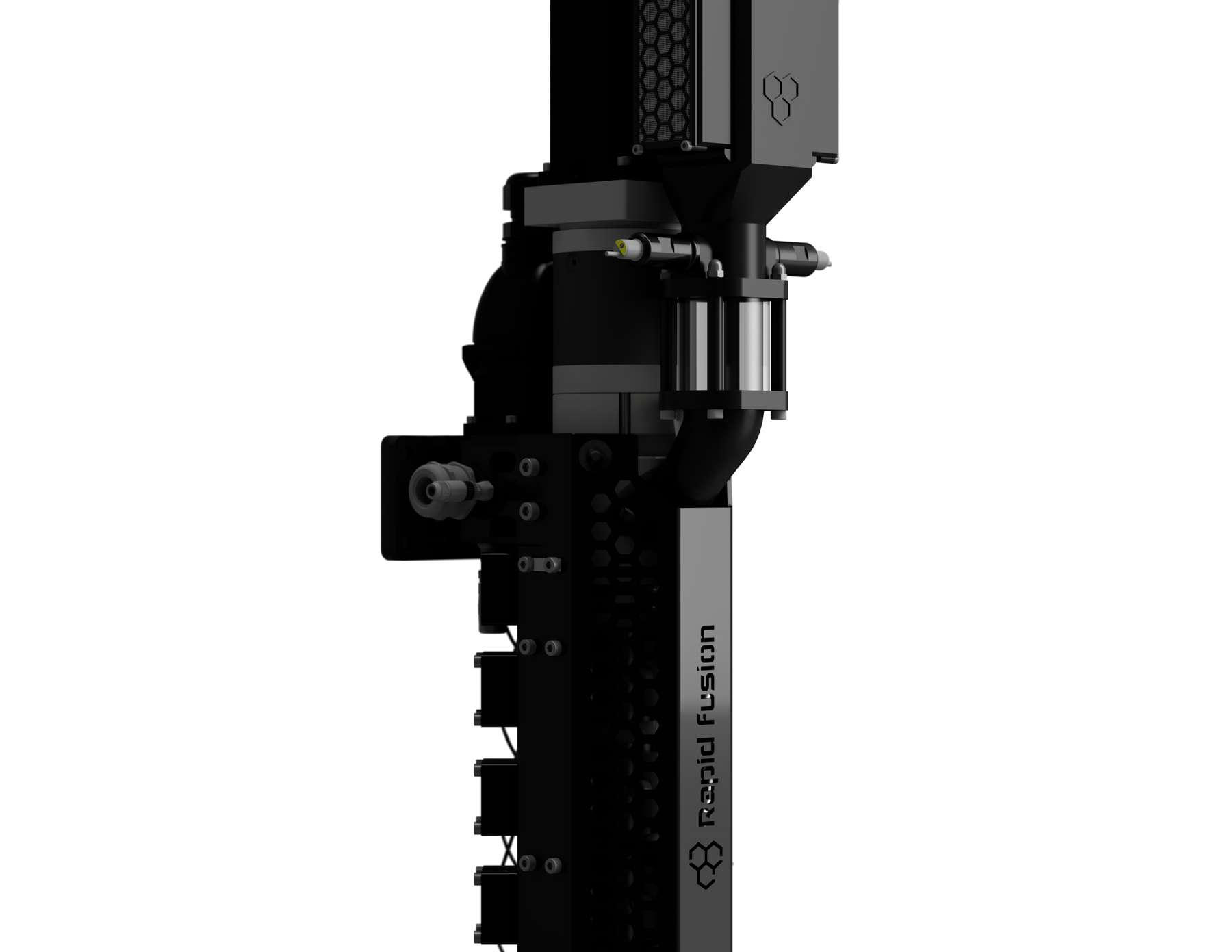

PE320 Extruder

The Rapid Fusion PE-320 Pellet Extruder is a versatile and powerful tool designed for industrial - grade 3D printing. Itoffers high - performance capabilities and can be seamlessly integrated into CNC machines and robots unlocking anew dimension of possibilities. With its advanced features and precise temperature control this extruder allows for efficient extrusion of a wide range of materials, including abrasive ones like carbon fibre. It combines power, precision, and versatility making it an excellent choice for upgrading and expanding capabilities on robot or CNC setup.

Key Features

- Unleash High-Temperature Printing:

The extruder can reach temperatures up to 450°C, allowing you to work with a wide range of high-temperature materials. - Powerful Motor, Seamless Performance:

Equipped with a robust Schneider motor, the motor provides Peak stall torque of 10.2 Nm and 8000 rpm speed, with a 1:25 Wittenstein German made gear box. - Precision Temperature Control:

The extruder has four heating zones that enables precise temperature control, enabling optimal printing conditions for different materials. - Versatility Meets Compatibility:

It is designed to handle abrasive materials like carbon fibre, providing versatility in material options. Additionally, it can be used to upgrade a CNC machine or Robot to a 3D printer expanding the possibilities of your existing setup. - Plug – and - Play Convenience:

The extruder can be seamlessly integrated into your current setup or used as a standalone pellet extruder.

Rapid Fusion

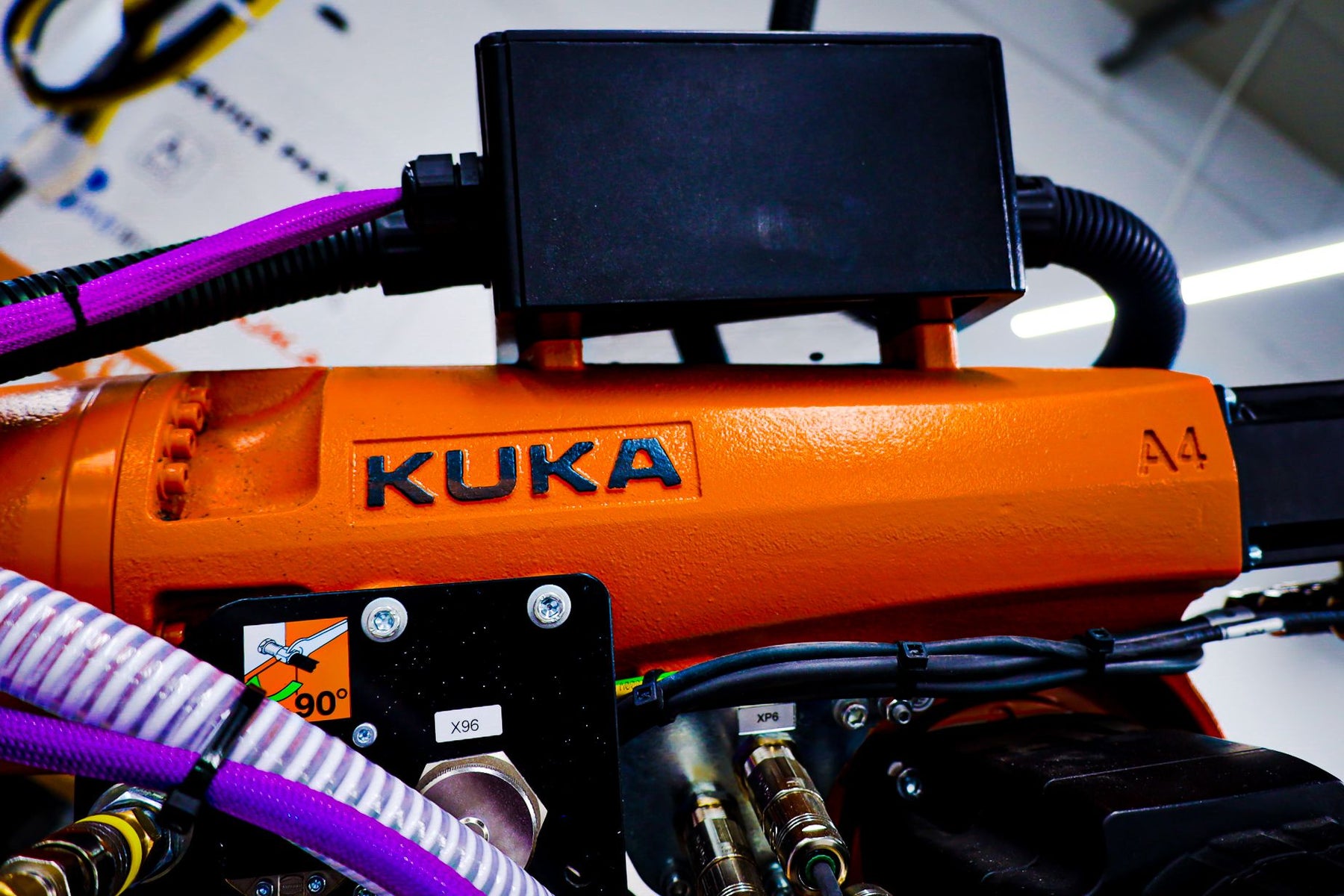

Robots

Rapid Fusion

KR 120 R3900-2 K 1 Robot

The KR 120 R3900-2 K is Robot of choice for Apollo. It is designed for a rated payload of 120 kg in order to optimise the dynamic performance of the robot. It is ideally suited for both additive, subtractive milling and other digital manufacturing processes – ensuring that your digital manufacturing cell deliver quality, efficiency and value for money – future proofing your business.

Rapid Fusion

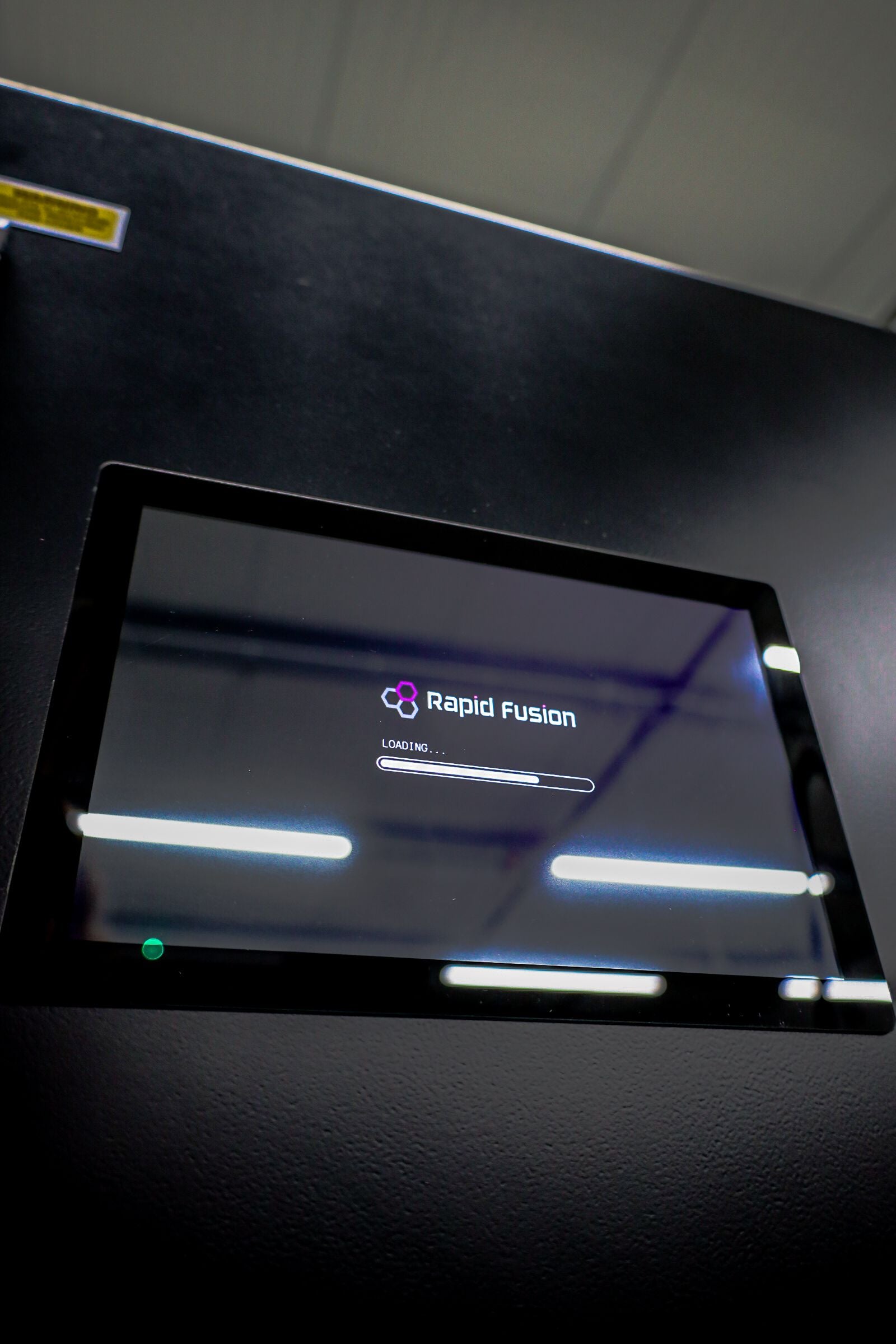

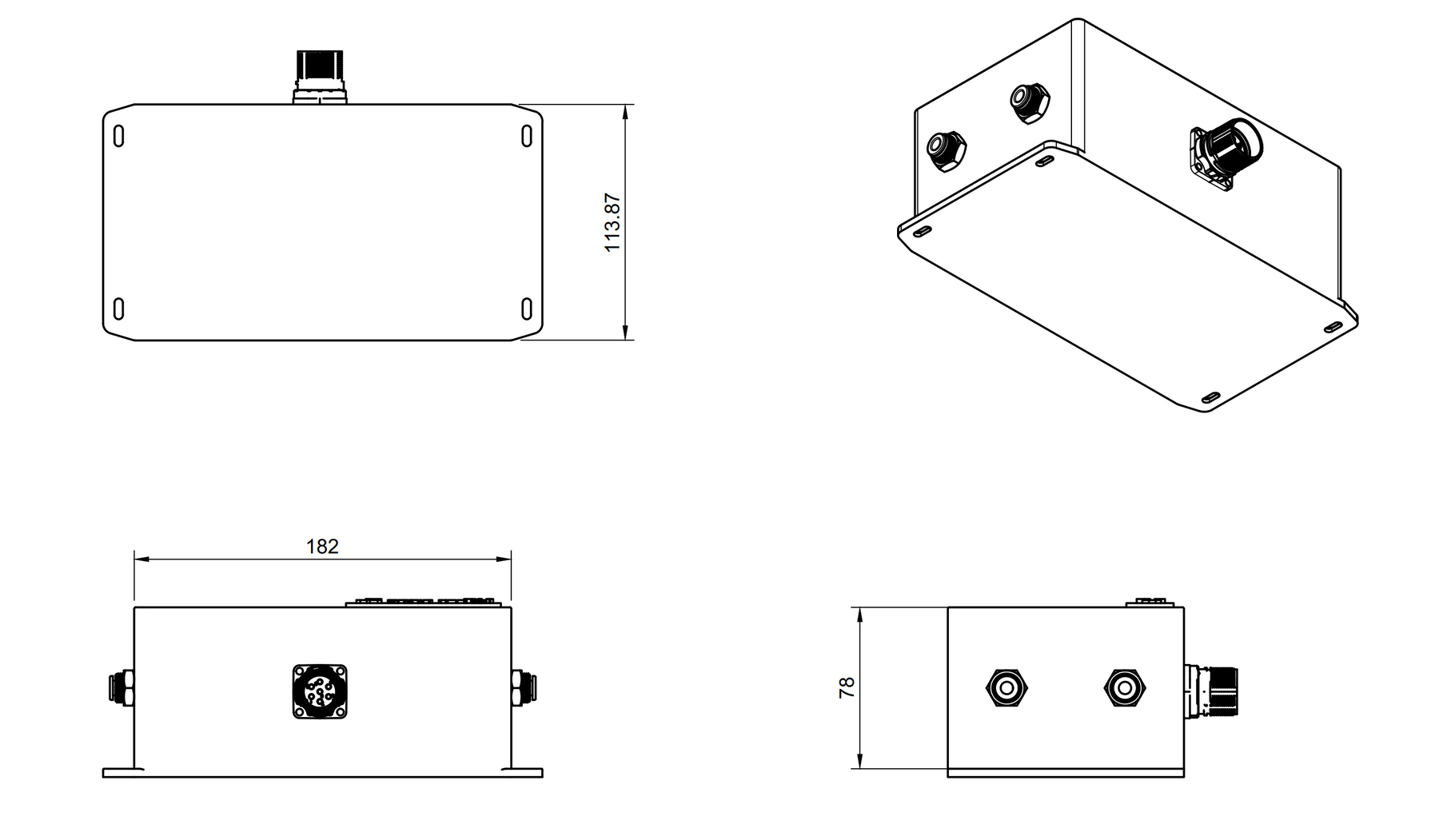

Epicurus Control

Introducing the Rapid Fusion Control Console, a powerful open-source control solution designed tomaximize the potential of additive manufacturing. With seamless integration with the Rapid Fusion PE320 and compatibility with other systems, this control console offers robust connectivity, precise temperature control, customizable IO capabilities, and enhanced safety compliance. Experience real-time control of the servo drive when connected to a robot for optimal printing results, unleash the power of 3D printing with ease. Unlock the potential of additive manufacturing with the RapidFusion Control Console. Here's what sets it apart:

- Seamless Integration:

Effortlessly connect with the Rapid Fusion PE 320 and other compatible systems for a streamlined workflow. - Precise Temperature Control:

Achieve optimal printing results with precise adjustments of extruders and bed heaters. - Real-Time Servo Drive Control:

Experience unparalleled precision by controlling the servo drive in real-time when connected to a robot. - Integrated Safety Features and Maintenance Key:

Ensure a secure working environment with integrated safety features.

- The maintenance key allows temperature override for maintenance purposes, granting access and control as needed.

- Integration into the Robot Safety Cell / Systems5.Intuitive10.1"Touch Screen with Pre-set Heating Zones: User-friendly interface with a spacious touch screen, offering pre-set heating zone profiles for easy navigation and control.

Rapid Fusion

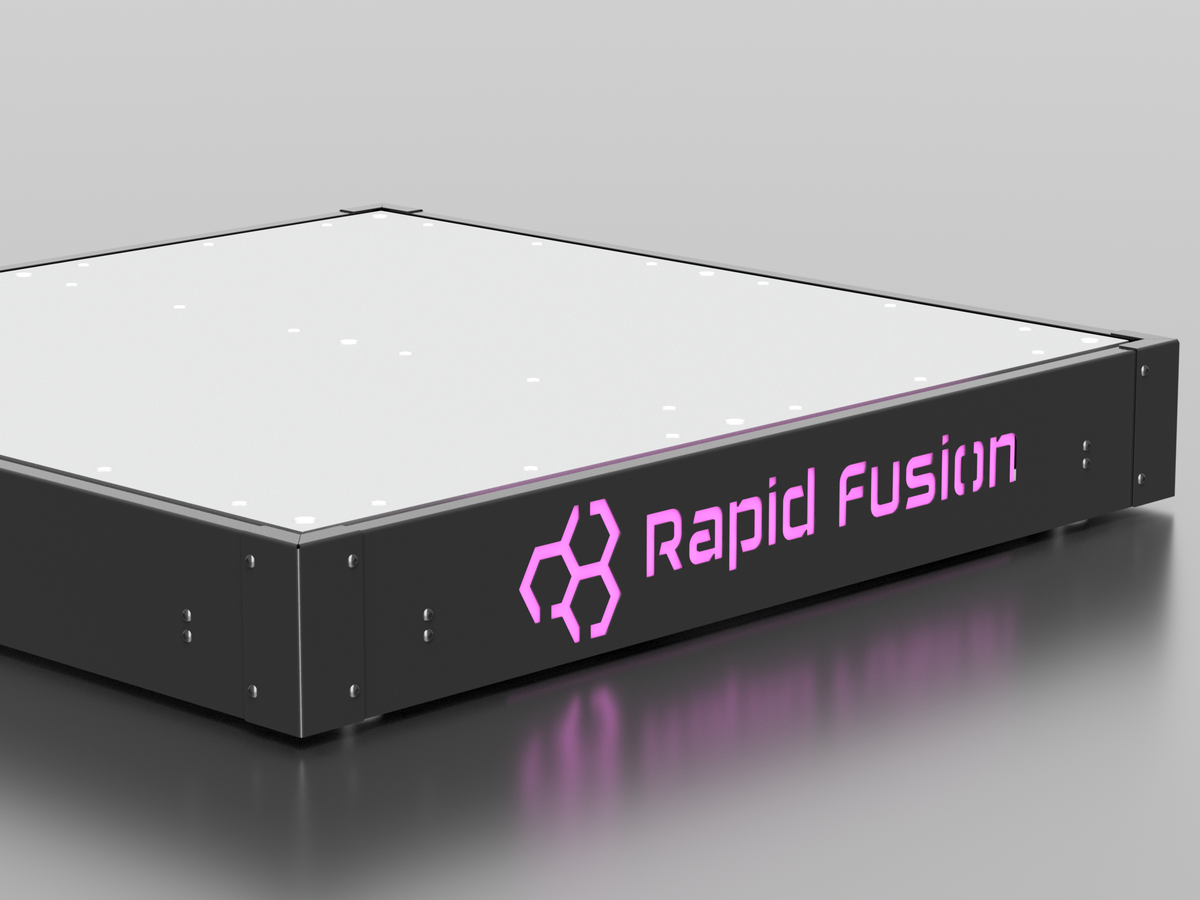

Atlas Heated Bed

Key Features

- Unleash High-Temperature Printing:

The extruder can reach temperatures up to 500°C, allowing you to work with a wide range of high-temperature materials. - Powerful Motor, Seamless Performance:

Equipped with a robust 1 kW motor, the extruder provides 4 Nm torque and 4500 rpm speed, ensuring efficient extrusion. - Unlock Scalable Manufacturing with the Modularity & Reconfigurability of the Atlas heated bed:

Each print bed can be linked and programmed in unison or independently – variations are limited only by your ambition

Rapid Fusion

Airflow System

Rapid Fusion

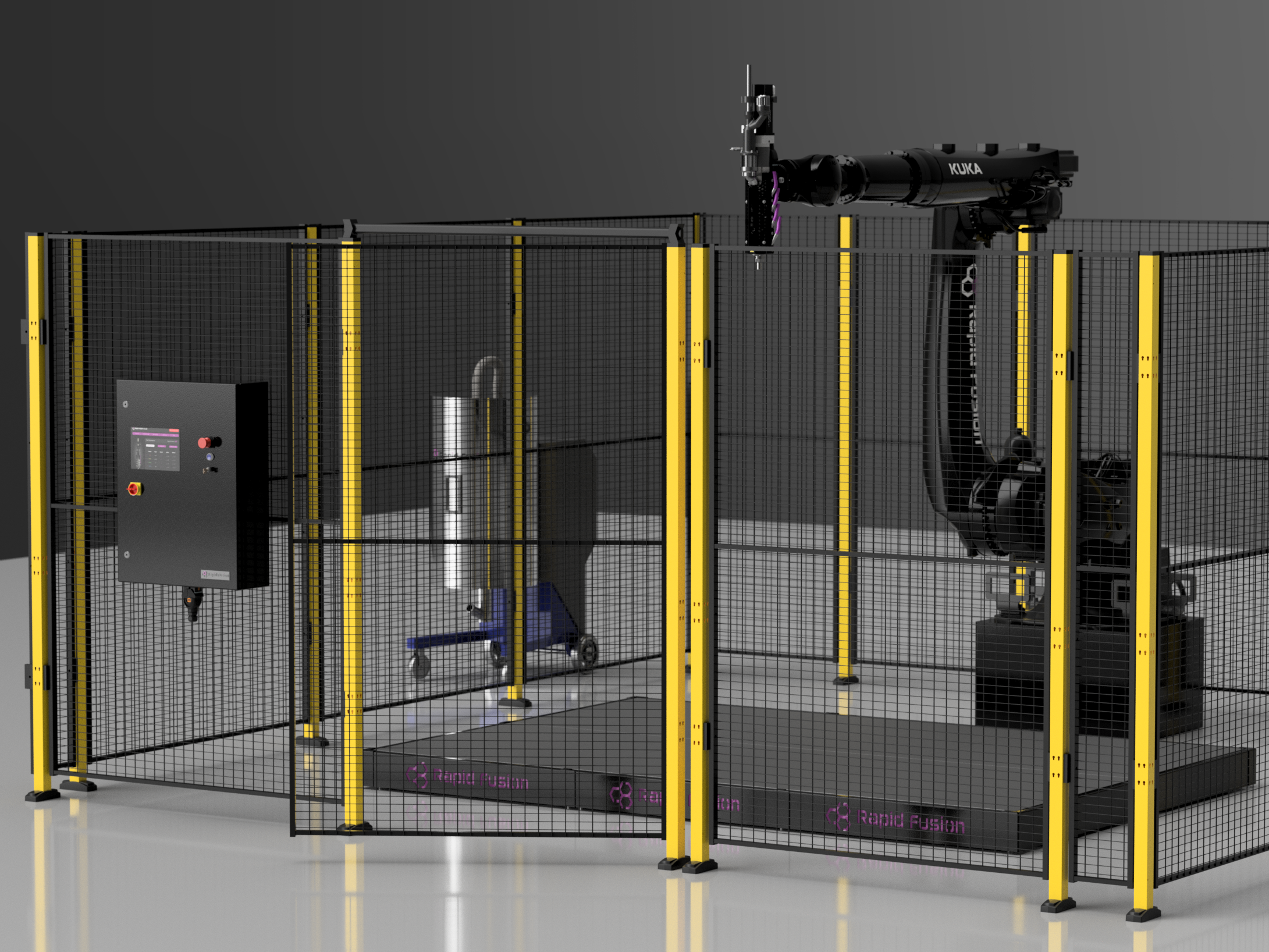

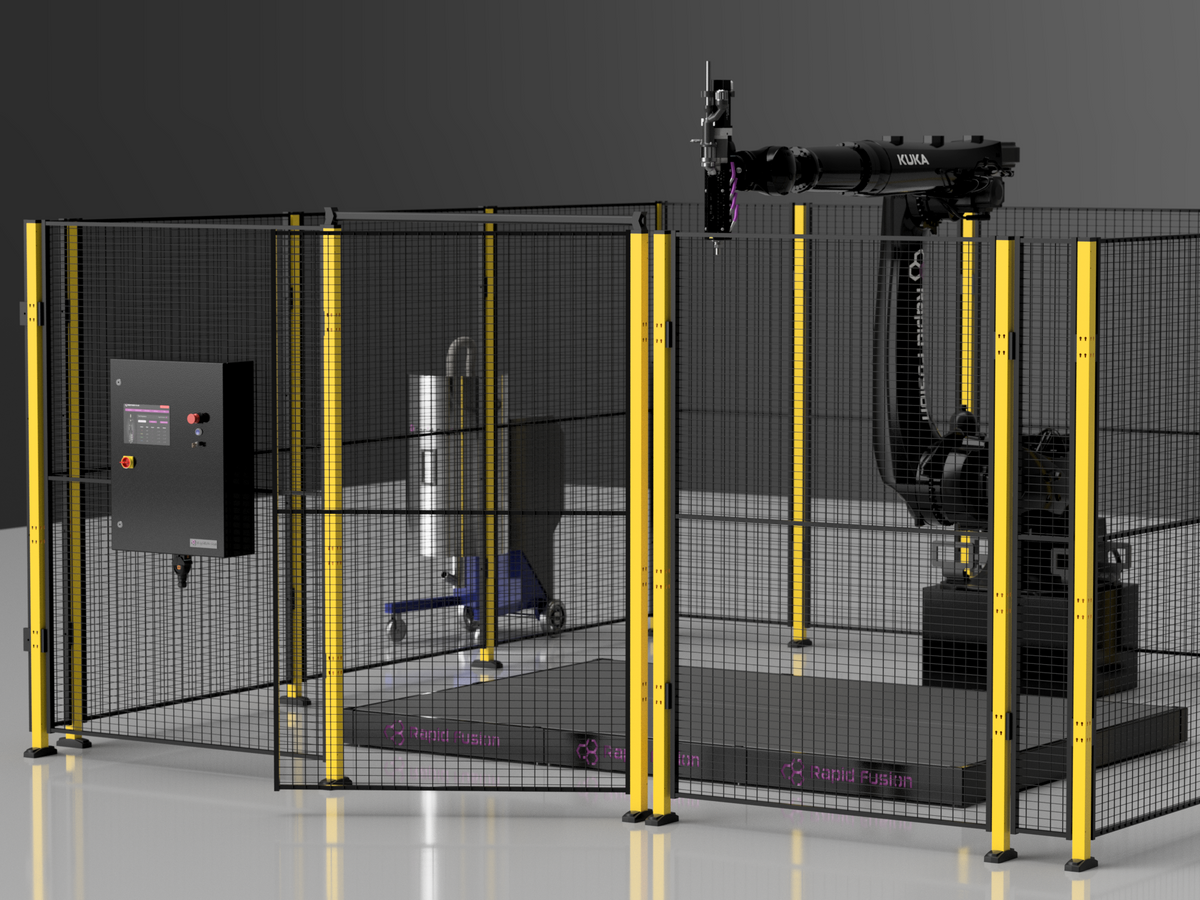

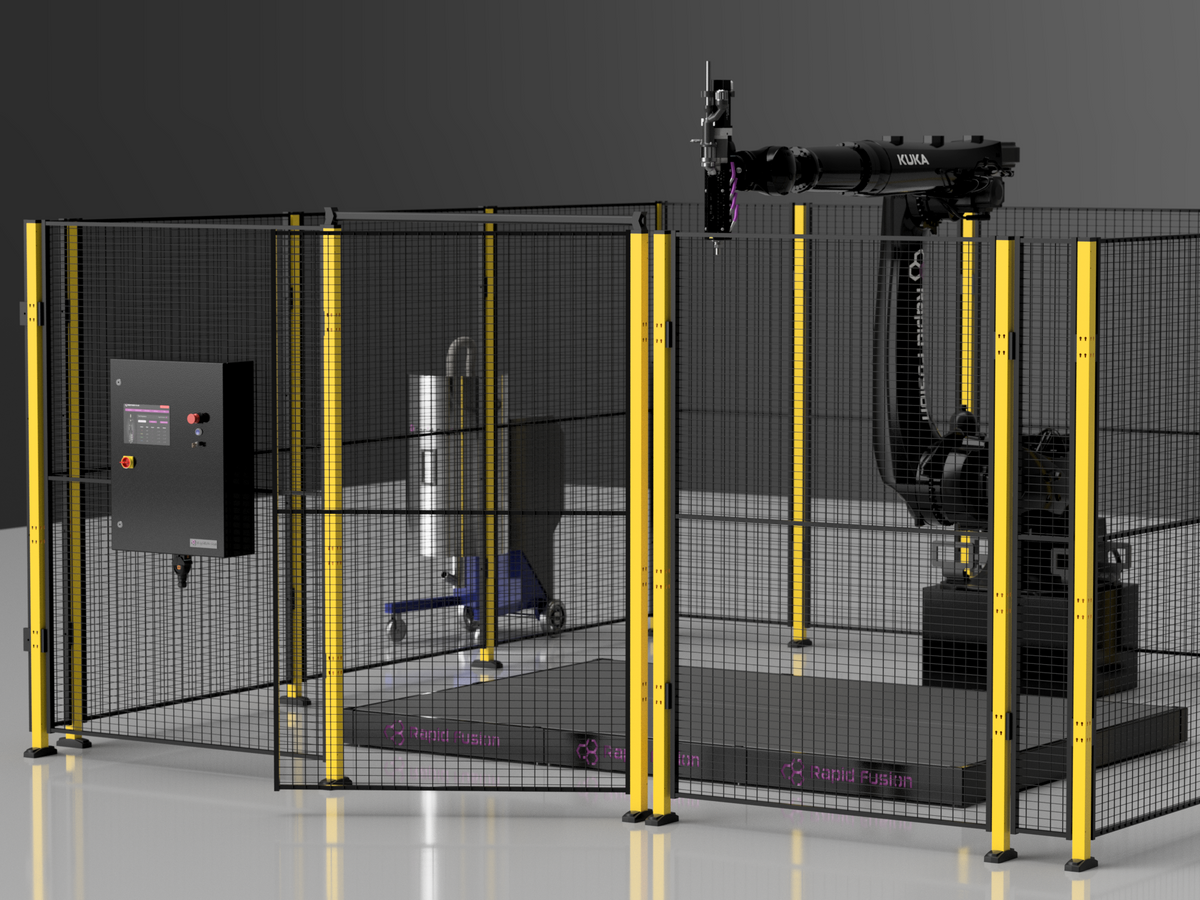

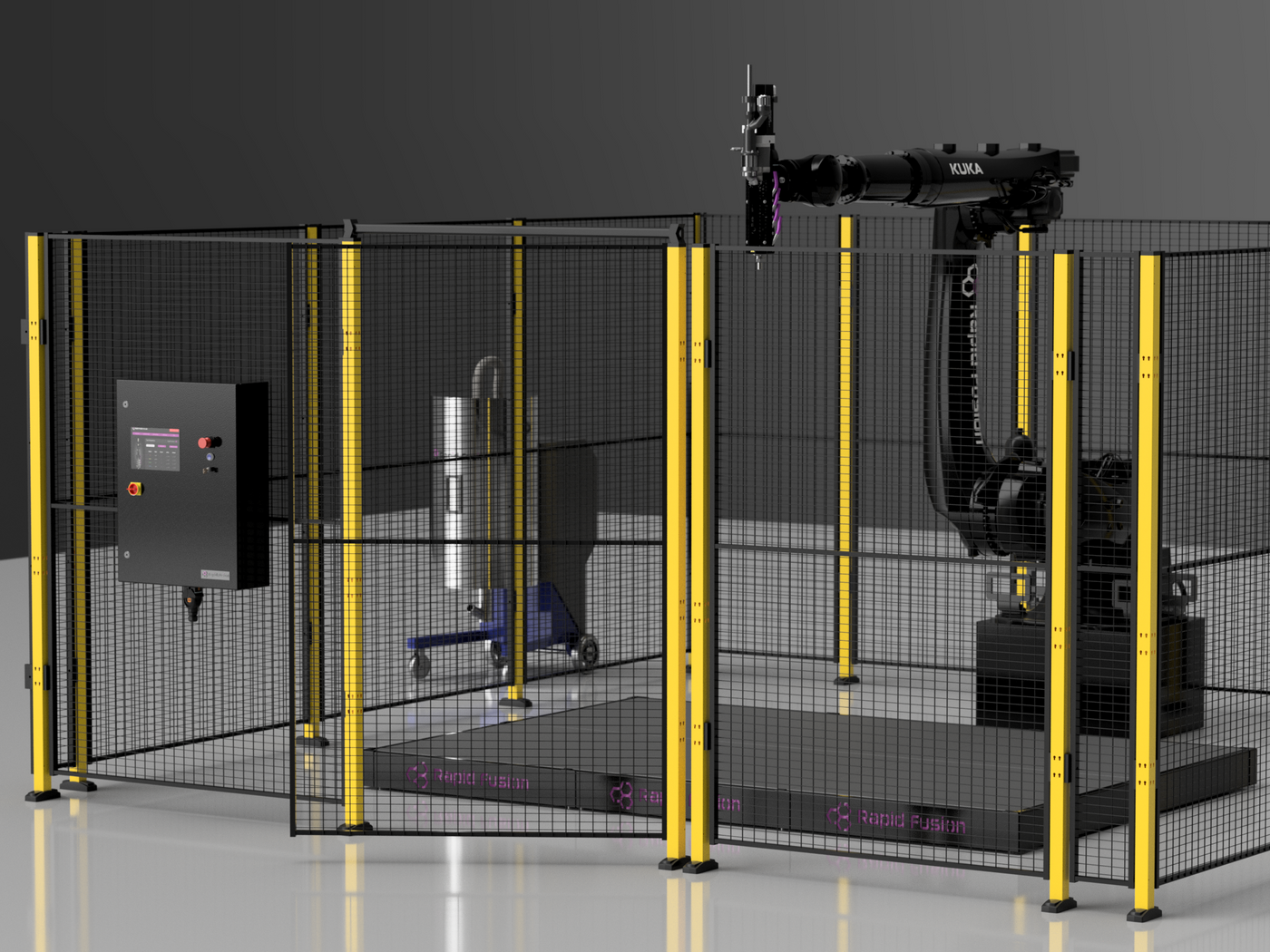

Enclosure

Rapid Fusion Safety Cell is developed based on three basic criteria: the system should be flexible, easy to install and meet all possible safety requirements and applicable legislation. The result is a very smart system with many advantages that are characteristic of machine guarding.

Thanks to the wide range of standard components and smart accessories, its guaranteed to meet every conceivable need. Another unique feature are that our different systems can be combined. Complete your machine protection with both cable trays and impact protection - all for maximum safety.

- A flexible machine guarding system

- Quick and easy installation

- Always complies with current standards & machinery directives

Rapid Fusion

Drier

Cam Software

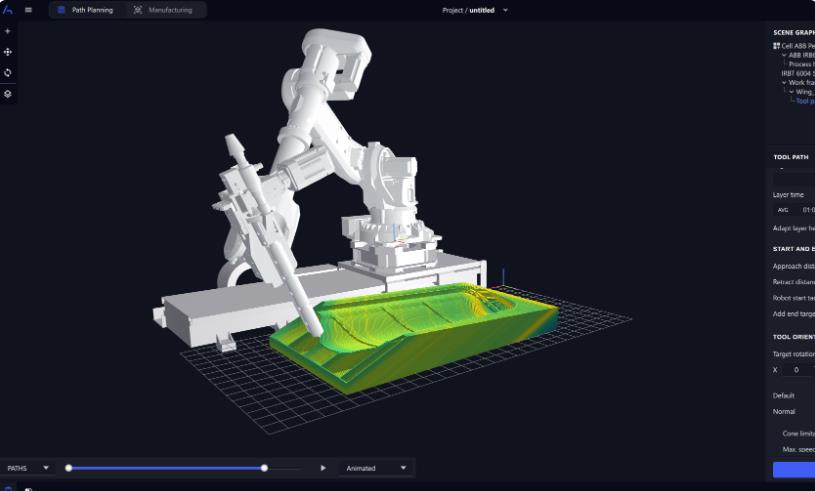

AiBuild

AiBuild’s software platform, AiSync enables fully automated toolpath generation for industrial additive manufacturing.

AiSync accelerates and automates the creation of even the most advanced, multi-axis toolpaths via a single, intuitive UI. Our intelligent AM platform replaces manual coding with visual programming, to completely simplify toolpath generation. A digital twin provides full visual build simulation and collision avoidance. Also equipped with powerful reporting and analytics, the entire 3D printing process is optimized and fully repeatable.

CAM Software

Adaxis

ADAXIS’ software platform AdaOne makes it possible to program and control robotic arms as large scale 3D printers for metal, plastics, and concrete.

AdaOnecovers every aspect going from design to finished part, with optimized support for a wide range of hardware, deposition technologies, and materials.