AON3D

AON3D Hylo High Temperature Industrial 3D Printer

A large turnkey industrial 3D printer for manufacturing end-use parts in open market materials, faster and easier than ever.

Easy, High Quality Results

Fully automated calibration and advanced material management deliver high quality results with the touch of a button.

High Precision, Automated Calibration on All Axes

A fully automated calibration process delivers new levels of repeatability with optical nozzle inspection and offset calibration, independent active-leveling extruders, and linear encoders.

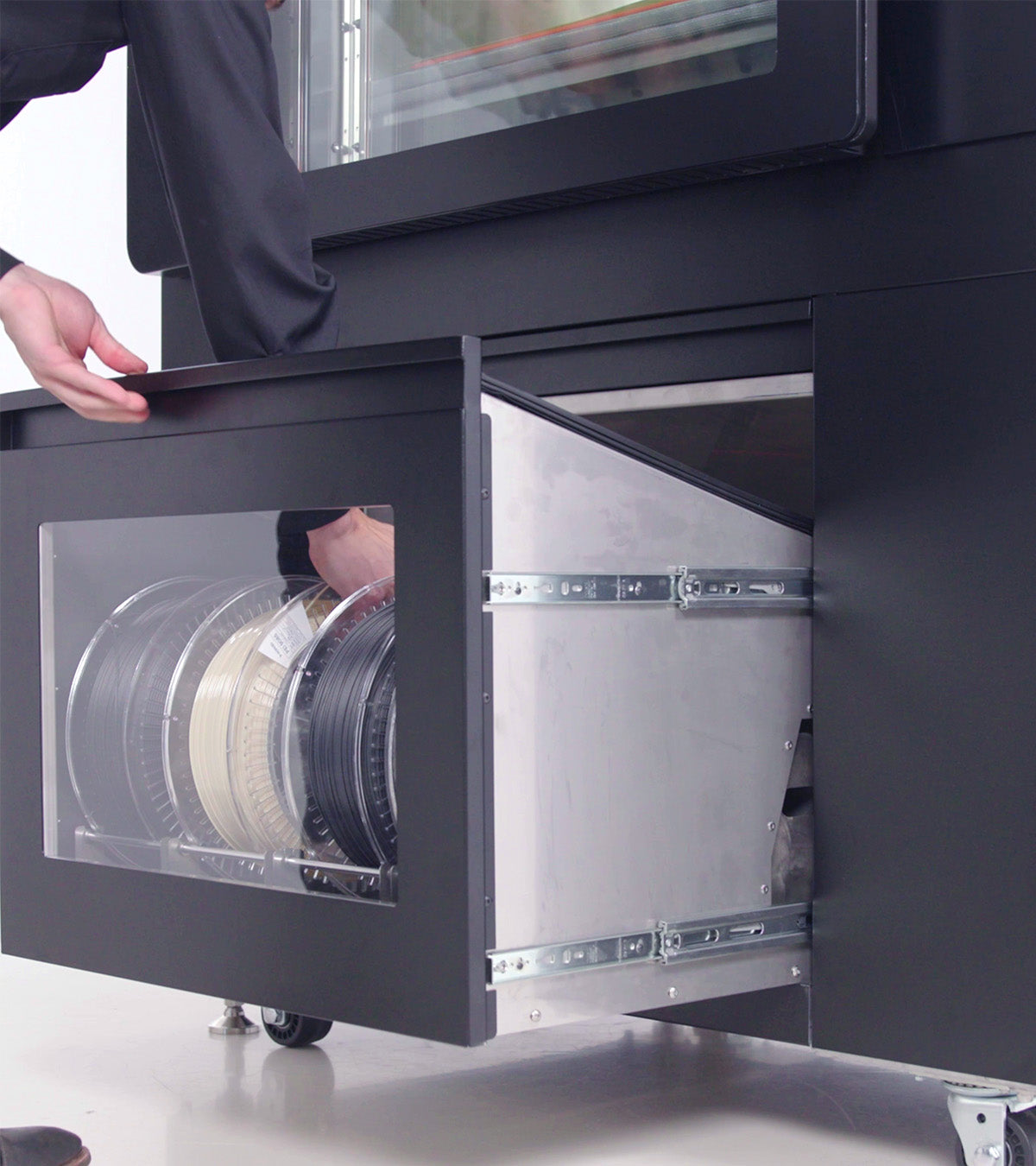

Advanced Material Management

Maximize part quality and consistency with a humidity-controlled and monitored storage bay, automated material loading/changeover, and filament diameter detection and compensation.

Integrated Quality Management Tools

Achieve consistent, high quality parts with over 25 integrated sensors for process control and monitoring. Analyze process logs in AON3D Basistm to quickly verify printed part quality and identify internal/external print defects.

Ultra-High Throughput

Achieve over 8x throughput with industry-leading print speeds, available duplication mode, and features that reduce time- and labor-intensive post-processing.

High-Speed, High-Flow Extrusion System

Print parts in a fraction of the time with industry-leading print speeds (up to 500 mm/s) and flow rates (up to 360 cm3/h).

Independent Dual Toolheads

Print complex geometries while reducing post processing with soluble supports or double your machine’s output by printing part runs with optional duplication mode (coming 2024). Independent active-leveling extruders compensate for planarity variations across the bed.

Raftless First Layers

High precision, independent active-leveling extruders with swappable, reusable build sheets provide perfect first layers.

Industry-Leading Part Performance

Achieve new levels of part performance with machine learning and open access to the world's most advanced polymers, including PEEK, PEKK, and ULTEM™.

Unrestricted Access to Open Market Materials

Access the newest advancements in additive manufacturing polymers or use Hylo’s fully open process controls to print custom polymers and alloys, no unlock fees or upgrades required.

Complete Convection Control

Achieve consistent part properties across the entire build volume with a thermally optimized, high convection 250°C build volume.

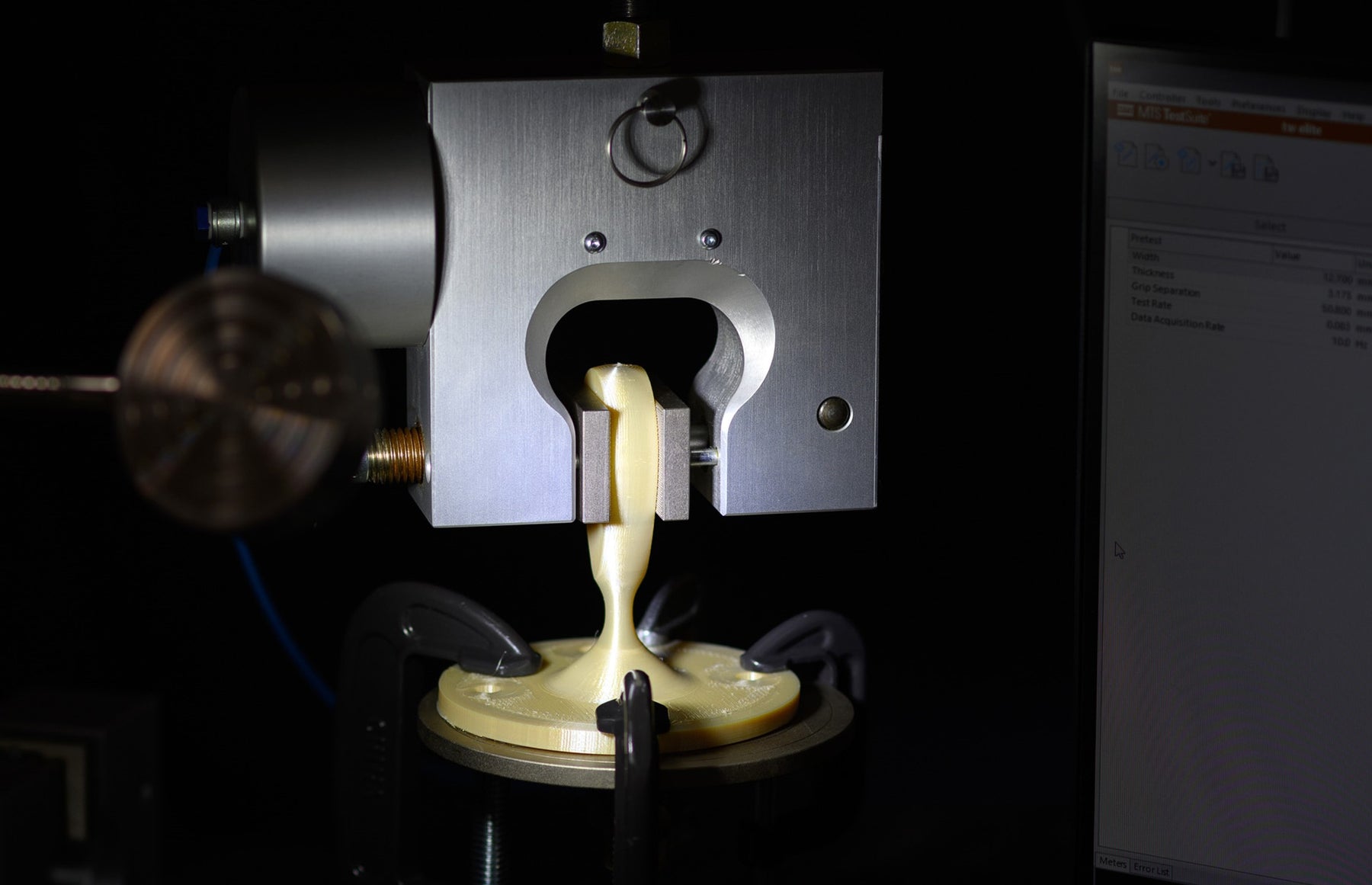

Composite-Ready

Print parts over 2X stronger and 6X stiffer compared to neat polymers. Hylo comes ready to print composites, such as chopped carbon fiber filled PEEK, where tensile strength can exceed 140 MPa and tensile modulus, 11 GPa.