[Interview] evo 3d unveils new rapid fusion pe 320 pellet extruder at tct 3sixty 2023 (by alex tyreer-jones of 3d printing industry)

![[Interview] evo 3d unveils new rapid fusion pe 320 pellet extruder at tct 3sixty 2023 (by alex tyreer-jones of 3d printing industry)](http://evo3d.co.uk/cdn/shop/articles/blog_graphic.png?v=1687355785&width=1100)

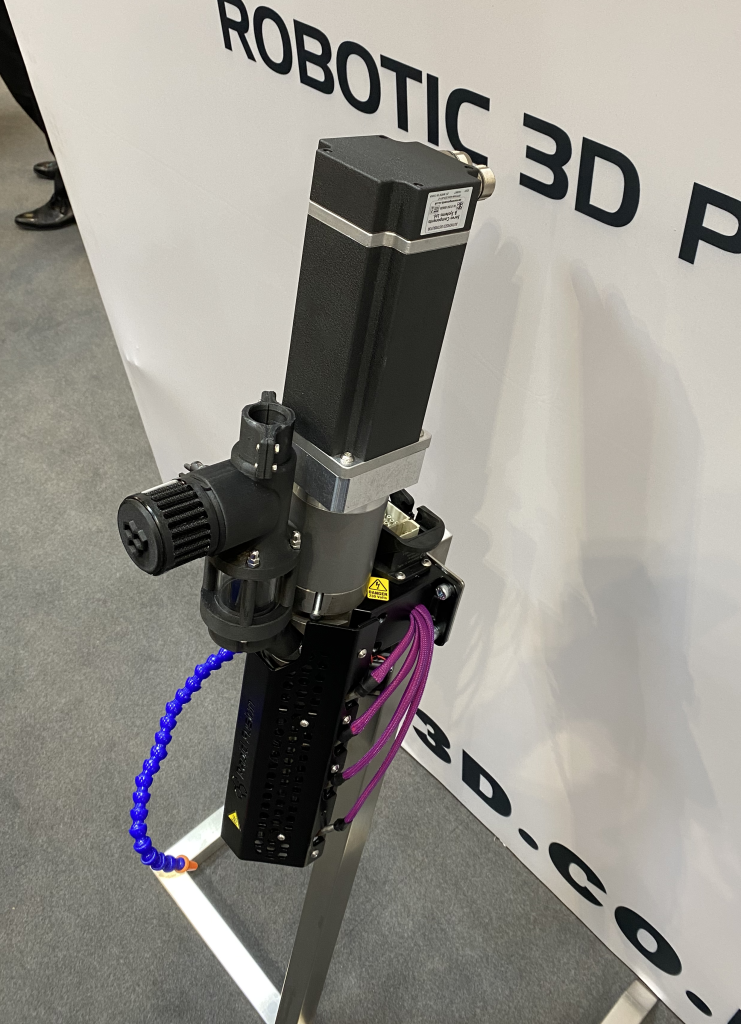

UK based 3D printer service provider EVO 3D unveiled their new Rapid Fusion PE 320 pellet extruder during TCT 3Sixty 2023 in Birmingham.

During the show, 3D Printing Industry spoke with Evo3D’s R&D Director Martin Jewell, Marketing Director Jake Hand, and Operations Director Martin Wood to learn more.

The first large format pellet extruder to be produced in the UK, the PE 320 is being developed under the Rapid Fusion brand. Rapid Fusion is EVO 3D’s new spin off company, which was also announced for the first time at TCT 3Sixty 2023.

According to Hand, a key draw of the PE 320 is the fact that it requires a low payload, but extrudes at high speeds of up to 12 kg/h, filling a gap in the market. “We built it because it doesn’t exist. What we’re passionate about is filling that gap” Hand explained.

The PE 320 is still undergoing testing, with the finished product expected to launch to market within the next 12 months. In the meantime, EVO 3D are looking to send a number of prototypes to their partners for more thorough, external testing.

EVO 3D announces Rapid Fusion

Based out of Exeter, EVO 3D offers a range of 3D printing services, such as reselling 3D printers and accessories, and providing technical support. Since launching in 2021, the company has built up a strong portfolio, partnering with a range of customers, including the National Manufacturing Institute of Scotland, the University of Cambridge, and London Electric Vehicle Company.

EVO 3D also has experience when it comes to robotic additive manufacturing, having already developed a range of 3D printing solutions for robots. Earlier this year, EVO 3D announced that they were expanding their EVO TECH 3D Robot Printing Cell range in collaboration with ADAXIS and REV3RD. This followed the company’s initial pellet 3D printing packages which were launched last year in collaboration with robot manufacturer KUKA, robotic 3D printing software developer Ai Build, and Canadian based OEM Dyze Design.

Building on this experience, EVO 3D is now extending the company’s robotic 3D printing capabilities further, through the creation of Rapid Fusion. “The time has come for EVO 3D to branch out and have Rapid Fusion as a manufacturer in its own right,” stated Hand.

Besides the PE 320, Rapid Fusion’s first flagship product, the company will also be announcing a range of new offerings in the near future. Hand stated that “We’ve got a range of other products set to be announced soon.” While Hand couldn’t offer specific details, he assured us that “the roadmap is going to be quite interesting,” teasing that we can “expect large format in many forms.” EVO 3D’s existing range of robotic 3D printing solutions, launched under the EVOTECH sub-brand, will also be further extended under Rapid Fusion.

The Rapid Fusion PE 320 pellet extruder

According to Jewell, a key feature of the PE 320 is its power-to-weight ratio. The pellet extruder’s weight of 22kg ensures that it is compatible as an upgrade to a CNC machine, or as an addition to a robot system such as the KUKA KR 22. Additionally, when used in conjunction with the dedicated console, or integrated into a customers existing workflow, the PE 320 can be used as a standalone pellet extruder.

The PE 320 incorporates a powerful 1 kW motor with 4 Nm torque, 4500 rpm, 400VAC, and 1:25 gear ratio for efficient extrusion. As a result, based on a desktop study and dependent on the material, the PE 320 can achieve a maximum output of 12 kg/h.

The PE 320 also offers wide ranging material compatibility, and can be used with abrasive materials like carbon fiber. Moreover, with a maximum extruding temperature of 500℃, the PE 320 can 3D print with a range of high-temperature materials. The PE 320 also provides precise temperature control through four heating zones, ensuring that these materials are 3D printed in optimal conditions.

Ultimately, the PE 320 is targeted towards industrial-grade applications. For instance, Hand points to the production of molds and large-prototypes as being a key use-case for robotic 3D printers, especially within the automotive industry. “If you want to print something fast with clever geometries, robots are the only solution to do that. So it’s got vast amounts of applications today,” claimed Hand.

It is also notable that the PE 320 is being manufactured within the UK, making it the first UK made large format machine, and the first pellet extruder to be produced in the UK. “We want to develop a range of UK built and developed products, because we’re not doing it, and we need to do more of it,” commented Hand. Whilst the PE 320 is manufactured within the UK, some parts, such as motors, need to be sourced elsewhere. However, Jewell highlighted that most of these parts are purchased through UK suppliers where possible.

Pellet extrusion within the 3D printing industry

Whilst pellet based 3D printing remains less widespread than other methods such as conventional FFF, pellet extruders can still offer major advantages for industrial-scale applications.

Last year, 2D printing specialists Seiko Epson Corporation (Epson) made its debut into additive manufacturing with an industrial grade pellet extruder. Incorporating unique flat screw extrusion technology, this system is said to be able to 3D print in a wide variety of pellet materials. This includes resin granules, metal pellets, and high performance thermoplastics like PEEK.

Elsewhere, German multi-material 3D printing technology developer AIM3D also offers industrial level pellet extruders. AIM3D’s ExAM 510 pellet extruder incorporates a substantial build volume of 510x510x400mm, and fast 3D printing speeds of 250 cm³/h. The extensive material capabilities of this system are also noteworthy. Thanks to a maximum build chamber temperature of 200℃, the ExAM 510 can process a range of engineering-grade polymers such as PEEK, PEI, PSU, and PPS. A number of metal based materials can also be used, including 316L stainless steel, titanium, copper, aluminum oxide, zirconia, and silicon carbide.

Featured image shows from left to right: Evo3D’s R&D Director Martin Jewell, Operations Director Martin Wood, and Marketing Director Jake Hand with the new Rapid Fusion PE 320. Photo by 3D Printing Industry.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.