Reasons to Support the Huge Benefits of 3D Printing

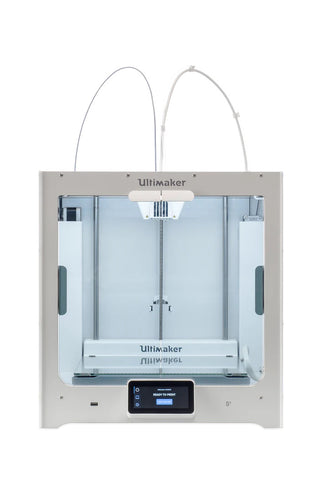

A 3D printer’s potential to deliver both mesh parts and complex shapes has brought about a lot of exciting possibilities for in-house production. Furthermore, no matter whether you are a start-up or an MNC. Ultimaker 3D printing puts both large-scale production and swift prototyping on your desk. Also, with a suitable filament and a job-appropriate 3D printer.

It is very much possible to replace both composite and metal parts with conventional techniques. Namely Computer numerical control (CNC) machining, laser cutting, and high-temperature injection moulding. What’s more, you can buy an Ultimaker 3D printer. Along with professional and industrial portable 3D scanners of varying configurations from Evo 3D.

It is very much possible to replace both composite and metal parts with conventional techniques. Namely Computer numerical control (CNC) machining, laser cutting, and high-temperature injection moulding. What’s more, you can buy an Ultimaker 3D printer. Along with professional and industrial portable 3D scanners of varying configurations from Evo 3D.

Convincing Reasons to Give 3D Printing a Try

Furthermore, in case you are new to the concept of 3D printing and have some doubts regarding whether to try a 3D printer or not. Then, this post will be of great help to you in revealing the most convincing reasons.

1. Swift Prototyping

3D printing (namely Ultimaker 3D printing) has a unique ability to create parts within hours. Thereby adding speed to the prototyping process. As a result, most of the stages in a product development life cycle are completed within less time. Evo3D engineers can suggest to you (through the contact us section) the Ultimaker model that will do justice to your purpose.

2. On-Demand Printing

Additionally, on-demand printing is another benefit of 3D printing. As there is no need to arrange additional space to stock inventory, unlike conventional manufacturing processes. Thereby saving a lot of space and money as there is no need to print wholesale unless essential.

Furthermore, the 3D design files are all saved in a virtual library. As they are printed using a 3D model as either a CAD (computer-aided design) or STL (stereolithography) file. Which means you can both search and print them when essential. What’s more, you can edit the design at a very low cost by editing individual files. Minus the waste of out-of-date inventory and investing in tools.

3. Speedy Design and Production

Also, relative to a part’s design and complexity. 3D printing can deliver objects within a few hours, which is comparatively faster than its machined or moulded counterparts. Furthermore, it is not only the part manufacturing process that one can save money on with 3D printing. But the design process can also be made very quick by creating STL or CAD files that you can print.

4. Waste Minimisation

Moreover, the production of parts asks for only the materials. That is essential for the part itself with small or zero wastage. In comparison to other methods that are cut from big blocks of non-recyclable materials. As a result, not only does 3D printing save valuable resources but it also reduces the cost of the materials being used.

Evo 3D feels its responsibility towards mother earth. That is why all its offerings including professional and industrial portable 3D scanners are designed keeping in mind to have an only essential carbon footprint.

5. Healthcare Innovation

In addition to that, 3D printing is of great help in the healthcare sector when it comes to saving valuable lives by printing organs for the human body namely kidneys, livers and hearts. More improvements and applications are being initiated in the healthcare sector. Thereby offering some of the biggest proceeds by using this technology.

6. Robust and Lightweight Parts

Furthermore, most of the 3D filaments are of plastic. Although these days new filaments made up of metal are also making their way into the market. But still, plastic filaments are comparatively more beneficial.

As it is lighter than their metal counterparts. This is greatly helpful in industries namely automotive and aerospace where weight matters a lot and is critical to ensure better fuel efficiency. Not only that, you can create numerous parts with tailor-made materials to offer certain properties. Like heat resistance, soaring strength or water repellence.

Conclusion

To sum it up, 3D printing greatly reduces both material use and other types of wastage. Along with enabling the production of lightweight, powerful parts that last longer, decreasing emissions across several industries at the same time. What’s more, a lot of 3D filaments are also eco-friendly.

Polylactic acid or polylactide (PLA) is biodegradable under commercial composting conditions, and Polycarbonate (PC), Polyethylene Terephthalate (PET) and (PET-Glycol) PETG (3 of the most common thermoplastics) are also recyclable.