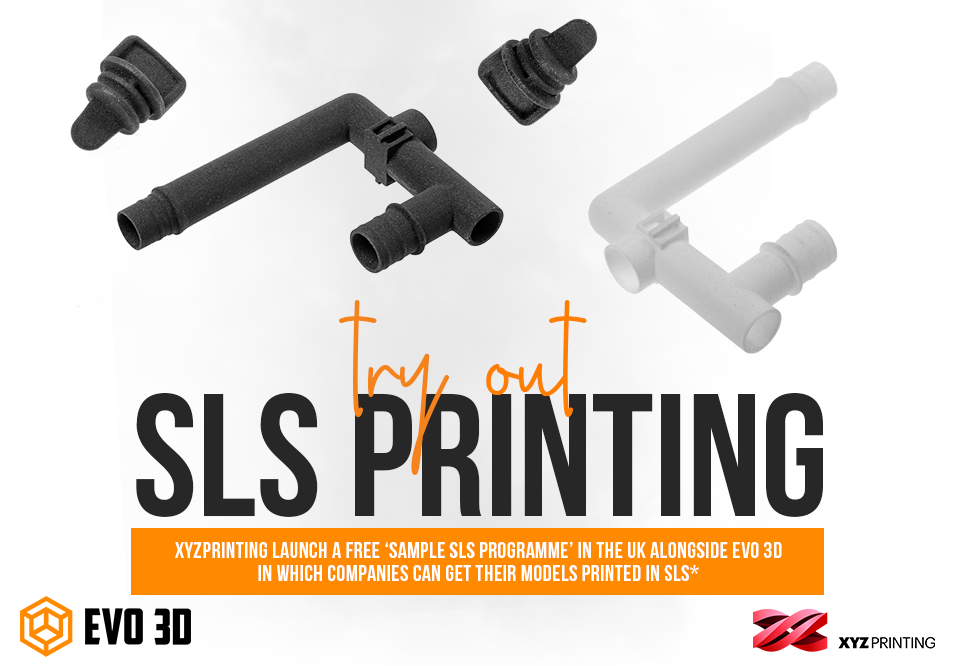

‘Sample SLS programme’ by XYZprinting and Evo 3D

XYZprinting in collaboration with Evo 3D are launching an SLS programme where UK based businesses may investigate the use of SLS technology by getting one of their own models printed as a free service. This will allow companies to see the benefits and main differences using a new technology such as SLS to manufacture / create your end product.

SLS is regarded as a popular printing technology as it allows printing very fine and detail models with isotropic properties without the need for supports. SLS is used often not only in prototyping, but also in production and manufacturing of final parts and items.

Material: PA12

SLS can help bring back production to SMEs without the need to externalize and depend on third party manufacturers, adding cost, lead times and compromising IPs over the models. This in turn offers the possibility to manufacture dozens of parts per day with minimal failures thereby reducing labour costs. Moreover, SLS offers companies competitive advantage over their competitors.

A great way to introduce SLS print into the company, for businesses searching to cover big production runs, there is great potential and cost-efficiency to invest in an in-house machine in which only a few months can cover the initial investment. Furthermore, there is no design effort to move from prototyping to production and changes to designs can be made within hours instead of weeks with almost zero setup cost.

In this manner, XYZprinting SLS solution MfgPro230 xS represents the best balanced SLS equipment in build size and Laser power (30W CO2 laser). More affordable SLS desktop solutions are considerably weaker, limiting the range of materials that the printer can utilize, decreasing printing speed and lowering overall printing quality.

XYZprinting MfgPro230 xS 3D Printer

One of the outstanding properties of the MfgPro230 xS is that it integrates an ‘open material’ platform making it one of the most versatile SLS machines. This is a great competitive advantage for XYZprinting, as most industrial SLS solutions on the market are limited to working with proprietary materials in closed systems.

Open Material Platform

XYZprinting has proven successful in SLS since starting up in 2020 and already by 2022 they are releasing a new model (MfgPro 236xS). This new model will not replace the existing model but instead offers an increase in laser power(60W vs 30W of the existing model) and a slightly bigger build size which makes it a considerable upgrade.

The programme allows for models up to 100x100x40 mm volume to be printed out in SLS free of charge. An ideal solution to check the print quality and tolerances that SLS can provide for your business. The scheme is limited to one model per client but can be extended to two prints for smaller models such as 20x20x20 mm.

Materials offered in this initiative by XYZprinting include PA12, PA11, TPU and PA11 CF. These available materials will give the client a good glimpse into some of the materials used with SLS technology and their different mechanical properties.

For clients looking to 3D print more than that provided in the scheme, on printing services basis, EVO 3D can offer quotations in a case-by-case basis.

* Please note, lead time for printed projects can be up to 4 weeks as there may be a need to simultaneously manage several requests at once.

Limitations to printed models: Limited to 1 model up 100x100x40mm or 2 models at 20x20x20mm per business address. Limited to PA12, PA11, TPU and PA11 CF materials. Note that materials offered in this scheme are not the material limitations of SLS printers, but these are the materials available in this programme.

For more information, please contact EVO 3D for details on how to participate in this program:

Email: oliver@evo3d.co.uk

Tel: 03339398184