The HRT Racing Team from the Harbin Institute of Technology won 3rd place in the 2018 Student’s Formula Electric China. As a sponsor, SHINING 3D worked closely with HRT Racing Team in the race, providing the racing team with not only metal 3D printing technology, but also expertise in automotive 3D printing, and making joint efforts in producing an electric racecar.

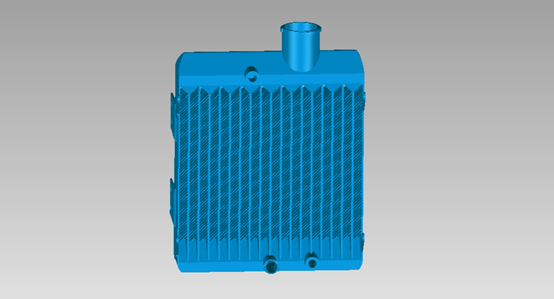

Racing car condenser

The racing car’s motor cooling system is an important factor that impacts its performance. The modification of a racing car’s condenser is very challenging. It took the racing team and engineers from SHINING 3D a substantial amount of time to optimize and modify the prototype.

The original condenser was manufactured by conventional processing, which needed to weld several parts together. The process was not only tedious but can also caused coolant to leak. SHINING 3D recommended the application of metal 3D printing technology to create a condenser with an integrated design, in order to ensure no leakage.

In structural design, the total heat dissipation power required for two condensers was 12 kW. According to test statistics, water temperature should be no more than around 48°C. Otherwise, electrical shutoff would be triggered by the motor controller at high temperatures (60°C) to protect it. By calculating the heat dissipated by the heatsink; influence exerted by reserved heat dissipation coefficient, water scale and oil pollution, the logarithmic mean temperature difference of the cooling medium, the heat transfer coefficient of the heatsink, and taking consideration of heat dissipation allowance, the actual heat dissipation area of the heatsink was 2.5 square meters. Based on these statistics, the racing team redesigned the current condenser.

After completing the design, SHINING 3D used the metal 3D printer EP-M250 with a building volume of 250mm*250mm*300mm. Aluminum alloy material was applied for the print. After post-treatment (heat treatment and sand blasting), it was delivered to the racing team.

After the 3D printed condenser with the new optimized design was printed, it was installed on an electric racing car for testing.

Statistics show that the temperature of newly-designed condenser was reduced by about 10°C compared to the previous condenser used in previous races in Japan. Heat dissipation performance had been significantly improved.

SHINING 3D successfully created motor cooling water jackets and condenser parts for the racing team, playing the advantages of metal 3D printing in product design and molding to the full. In the design and manufacturing of racing cars, metal 3D printing gives designers more flexibility and freedom to create. Not limited to manufacturing process, it realizes small and complex structure manufacturing together with sound stability and lightweight body, elevating the overall performance. Metal 3D printing will also greatly promote the development of traditional auto market with its low cost, high efficiency and high quality.