Bulgin - Rapid Response Team as a guarantee of quickly made bespoke parts

Customer: Thisen Bird, Project Engineer, Bulgin Ltd

Country: England

Industry: Industrial Products

Application: Prototyping

Uses: Pre-Production Prototype, Enclosures, Containers

Top reasons: Reactivity, Low Operating Cost, Accuracy

Background

With the introduction of a dedicated Rapid Response Team, Bulgin can provide fast turnaround times on bespoke customer projects and requirements. They range from the manufacturing of cable assemblies to bespoke product customisations and developments

Bulgin hopes to provide a response to the customers’ query in 48 hours. From there, they can supply samples of their desired product.

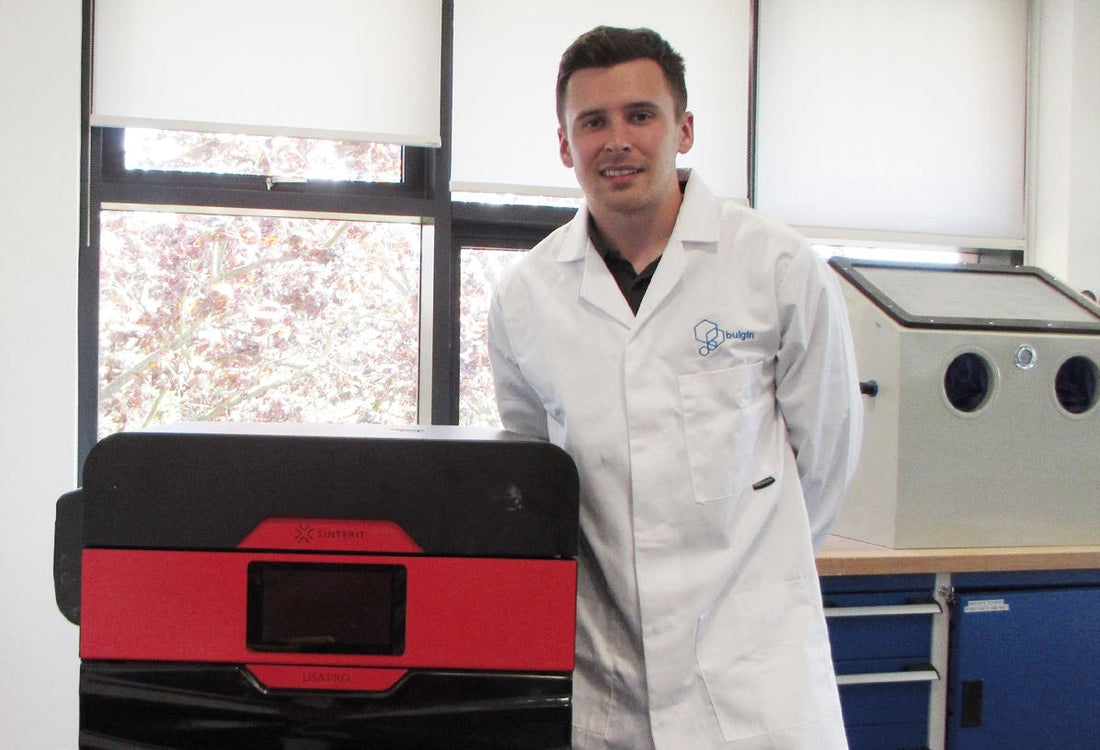

As Project Engineer, Thisen Bird is heavily involved with shipping these samples to customers, ensuring they are delivered in a timely manner for them to win the contract with the customer to produce greater volumes.

Problem

The problem arose when they needed a fast solution to be able to deliver those prototypes to the customer quicker than any other competitor. Before, they would need to request samples to be made by local rapid prototyping companies which would increase the delivery time of these prototypes to the customer. With the launch of the RRT, they have set the goal for a fast turnaround of models for the customer to inspect in their hands so they need a solution to get these samples quickly and reduce their cost of having pieces produced and not winning the work.

Solution

Equipment used: Sinterit Lisa PRO 3D Printer

Material used: PA12

The solution was investing in a 3D printing technology that could enable them to produce high-quality samples for the customer. The Lisa PRO from Sinterit was identified, which allows them to create high-quality pieces with minimal post-production treatment.

With in-house rapid prototyping technologies, including Silicon Moulding and 3D SLS Printing, Bulgin can produce working samples for customer evaluation and testing. Never before has the process of enquiry to sample delivery been so seamless.

This approach eliminates the need to have samples manufactured by a third party or invest in tooling for injection moulding methods. Therefore, purchasing this printer means they can deliver samples to customers quicker than before and enable them to win more work due to this investment in the Sinterit 3D printer.