Selling fast!

Get yours while you can.

Your cart is empty :(

Continue shoppingYour cart

Estimated total:

£0.00 GBP

£12,521.74

Couldn't load pickup availability

Secure your shopping experience with various safe and trusted payment methods.

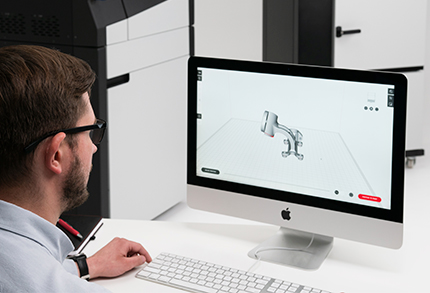

Automate the correct preparation of your materials for accurate, strong, and high-quality parts. The MMS enables connected productivity, repeatability and full traceability of the printing process.

3DGence MMS automates material storage, preparation, and post-print annealing – making successful printing of Ultra-Polymers like PEEK, ULTEM™, and Composites accurate and simplified.

As the shift from prototyping to end-use parts has become a reality through industrial grade 3D printers and advanced materials, automation and pre-configuration ensures print success.

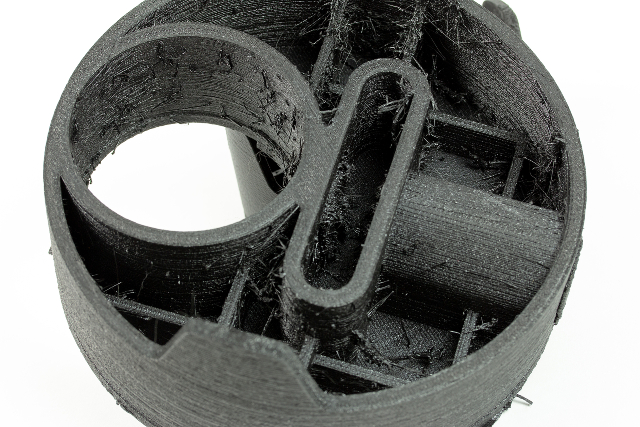

Improper handling and preparation of materials can result in moisture creep, print failures, warping, and low visual quality – resulting in inaccurate parts and significantly reduced productivity.

Ensure print productivity, part integrity, and the highest quality with our Material Management System.

-Select materials from our Certified Open Material Database and register them to get full material traceability.

-Each spool of material purchased from 3DGence is equipped with an NFC tag with a Unique ID. Once selected, the material is registered by scanning to the MMS and integrated with 3DGence CONNECT.

-The material associated to the print is traced in the print process, and can be viewed on the MMS or 3DGence INDUSTRY line printer.

-The associated material and print process is registered and stored in process logs, accessible in 3DGence CONNECT™.

Avoid low quality and print failures due to unprepared materials.

-Certified Open Material configurations are pre-programmed in the MMS according to manufacturer technical specifications.

-A user friendly touchscreen interface will quide you effortlessly through the material and compartment selection.

-Each material will be properly dried, moisture controlled, and prepared according to material specifications.

-Entire workflow from material selection, configuration, compartment assignment, readiness is streamlined and intuitive

-The capability to post-anneal PAEK materials results in significantly enhanced strength, durability, and anti-corrosivity.

-The 3DGence MMS system includes a compartment that can also be used for annealing in addition to material preparation.

-The 3DGence know-how of PAEK annealing cycles is programmed and configured into the MMS system, and active in seconds.

-Anneal AS9100 PEEK, Victrex AM™ 200, CF-PEEK, and other Certfied Open Materials through a few short steps in the MMS interface and be ready to receive ultra-strength parts.

Parts printed from materials that are not stored properly have lower mechanical properties and visual quality.

MMS pre-programmed preparation modes ensure durable and accurate prints without visual defects.

£12,521.74

Selling fast!

Get yours while you can.