Selling fast!

Get yours while you can.

Your cart is empty :(

Continue shoppingYour cart

Estimated total:

£0.00 GBP

Secure your shopping experience with various safe and trusted payment methods.

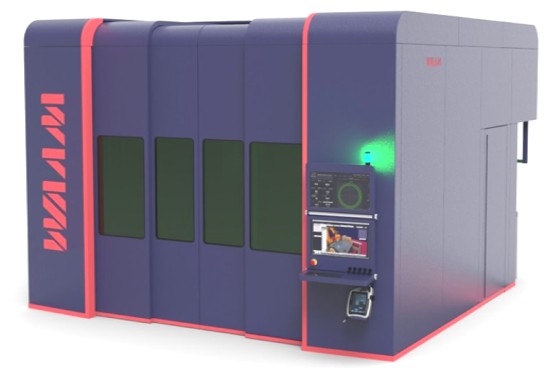

RoboWAAM – PTA / P-MAX: Industrial-ready system for high performance deposition, combining productivity, efficiency, and advanced material capabilities

| Specification | Details and optional upgrades (marked with *) |

|---|---|

| Machine Size | W4500 x L5550 x H3565 mm |

| Print envelope | Up to L1800 x W1200 x H1500 mm³ (configuration dependent) |

| Control System | Kuka KRC5 with Siemens PLC |

| Fume management | Local fume extraction + *global fume extraction and filtration |

| WAAM Variant | Plasma Transferred Arc (PTA) or *Dual Wire Plasma Transferred Arc |

| Welding power source | EWM Tetrix 552 Synergic Plasma |

| Wire Feeder | Abicor Binzel accurate push pul system |

| Axes | 6 (robotic arm) + 2 (servopositioner) |

| Materials | Titanium alloys, stainless steel, nickel alloys, and others *Multi material functionality |

| Rotational table | 500 kg payload (upgradable to 750kg payload) |

| Sensors | Process camera, Weld sensors *Pyrometer, *IR camera, *Shapetech |

| Controls | Manual Wire position control *Auto Wire control using Images based AI *Auto arc start with interlayer temperature control *Auto layer height correction |

Selling fast!

Get yours while you can.