Builder 3D

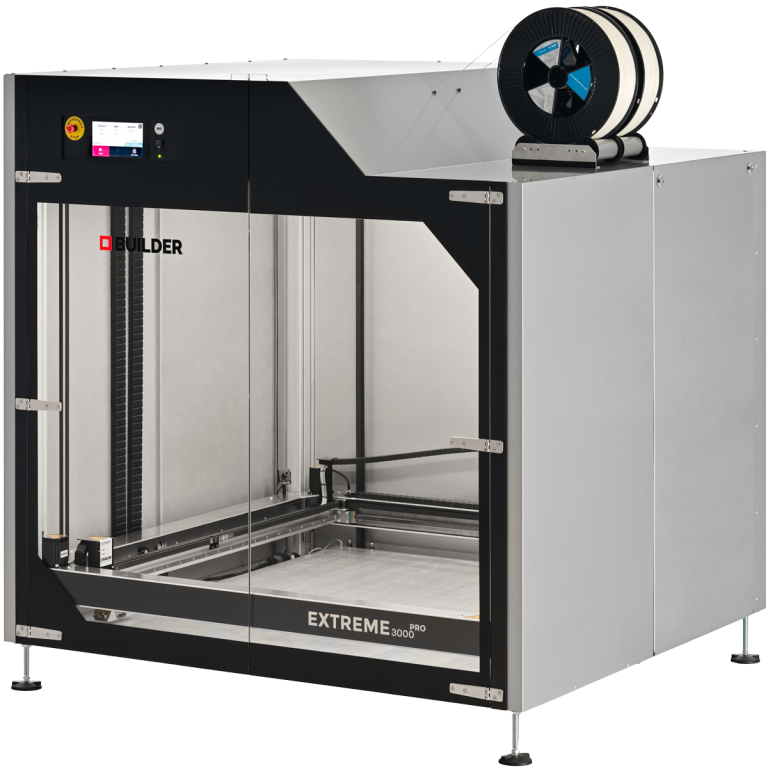

Builder Extreme 3000 PRO

BUILDER EXTREME 3000 PRO

Massive build volume

With a large build volume of 1100x1100x820 mm (XYZ) The Extreme 3000 PRO is one of the biggest large format 3D printing solutions available on the market today. With such a volume; Engineers are able to create full size products for automotive, aerospace and architectural sectors within days.

Versatile Dual feed extruder

The Dual-Feed extruder has been developed by Builder themselves and has a singular nozzle, which is easily interchanged to 3 different diameters which helps optimise between quality and print time. The machine enables to print dual-material objects, as well large objects made of one material.

0.4 mm nozzle (up to 0.3 mm layer height)

0.8 mm nozzle (up to 0.7 mm layer height)

1.2 mm nozzle (up to 0.9 mm layer height)

Removable side panels

The incorporation of fully enclosed housing and the heated bed positively influence the print quality of the minute details of your print. The machine comes with 2 removable side panels for easy access to your print, this is particularly useful if the object is large or for maintenance reasons

Effortless 3D Printing Control

The responsive, full-colour 7 inch touch screen makes operating the Extreme 3000 PRO straightforward, as well as being placed at an ergonomic level, it allows you to have complete adjustment control over the 3D printed part and your Builder extreme 3000 Pro. Print speed, temperature and filament change can all be adjusted here.

Trouble free features

The Builder Extreme 3000 PRO comes with integrated battery pack Technology that resumes the operation after a power cut.

Specifications

Print volume-1100x1100x820 mm (XYZ)

Print speed-Up to 300 mm/s (depending on geometry and nozzle size)

Layer height resolution Up to 0.9 mm

Features Filament detection Battery pack (restore after power failure)

Easy to swap nozzles

BOFA air filter system (optional)

Outer dimensions-151x138x160 cm

Shipping dimensions-155x165x165 cm

Weight-275 kg

Power rating-1800 W (at peak)

Technology Fused Deposition Modelling (FDM)

Process Print head Dual or Mono Print speed Up to 300 mm/s (depending on geometry and nozzle size)

Travel speed-Up to 500 mm/s

Build plate-Aluminium

Heated bed-Up to 60 degrees

Bed-levelling- Automatic

Feeder type-Direct drive

Nozzle diameter -0.4, 0.8 and 1.2 mm

Connectivity- Wi-Fi, USB, Ethernet

Display-7-inch full colour touch screen

On-board camera -Snapshots on desktop or mobile device

Supplied software-Simplify3D

Filament diameter- 1.75mm

Materials- PLA, PET, PVA, PRO1 (ABS Replacement), Flexible Filament