Builder 3D

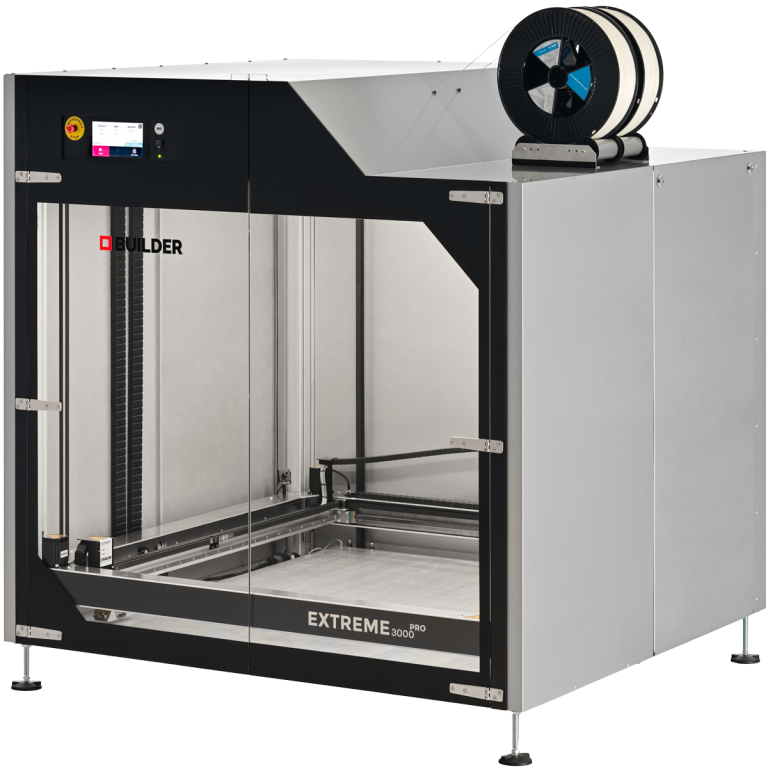

Builder Extreme 3000 PRO

Extremely large build volume

The Extreme 3000 PRO has an extremely large build size of 1100 × 1100 × 820 mm XYZ. This allows you to print full size prototypes, parts and moulds in one piece. You can even print multiple parts in one print job.

Easy access

The Extreme 3000 PRO has been designed to print extremely large parts, but you also need to be able to remove the printed parts easily. That is why the machine has removable panels on the left and right side. By removing the panels, you have easy access to remove prints or do any maintenance to the machine if needed.

Easy to use

Despite the large build size the machine is easy in its use. The large touch display allows you to have full adjustment control over the machine while printing. Large format 3D printing becomes easy and worry free with features such as filament detection and a battery pack when there is a power loss.

Different nozzle diameters

The Extreme 3000 PRO comes with 3 different nozzle diameters which allow you to choose the right print quality and time for your specific needs. A 0.4, 0.8 and 1.2 mm nozzle are included with the purchase. The 0.4 mm nozzle is often used for parts that need to be accurate, the 0.8 mm for printing prototypes within days and 1.2 mm for printing parts within several hours and parts that will be post processed.

Builder 3D

Builder Extreme 2000 PRO

7-inch touchscreen – easy to use interface

The 7-inch touchscreen allows you to have full control over the Extreme 2000 PRO and the printed object. You can control the nozzle and bed temperature, but also adjust the light, perform the filament change and many more. What is more, you can play the maintenance instruction videos. With the on-board camera you can check the progress of the print directly from your mobile device.

Dual-Feed extruder – most versatile solution

The innovative and versatile direct drive extruder has been designed in-house for the continuous 24/7 printing.

The Dual-Feed extruder is able to print dual-coloured objects, but can also be used as a mono extruder when inserting two of the same filament spools. The easy to swap nozzle can be replaced for the one of a smaller/bigger diameter in order to optimize print quality vs time.

Fully closed housing

The fully closed housing combined with the heated bed positively influences the print quality of the object but also reduces the sound of the machine by 40%. The transparent doors allow you to monitor the printing process at all times. For safety reasons the doors can only be opened when the print is paused. The Extreme 2000 PRO is prepared for the air filter integration and the BOFA air extractor can be added to the machine as an option.

Design

The Extreme 2000 PRO has been designed efficiently in order to incorporate all of its key features without sacrificing the print volume. Despite its huge operating area, the Extreme 2000 PRO is optimal for all workspaces. The filament spools and control box are integrated in the closed housing and open for easy access, when slightly pushing the panels. The 7-inch touchscreen is ergonomically placed at a level comfortable for the user.