ROBOT 3D PRINTING PARTNER

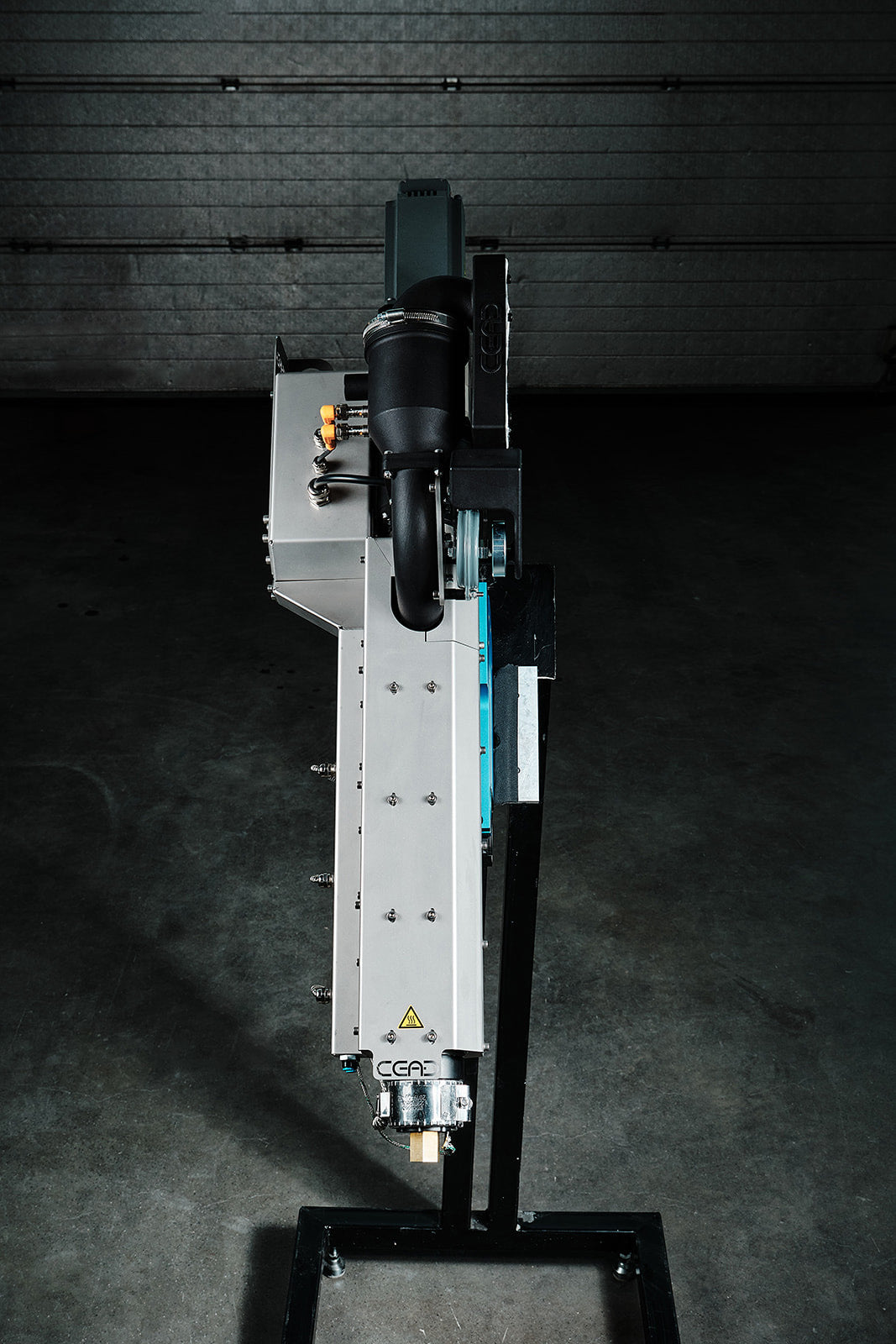

CEAD

CEAD delivers technology and helps with the implementation of large scale thermoplastic composite 3D printing solutions

technology solutions

CEAD offers its printheads as technology components that can be used to build large scale 3D printers. These printheads are often referred to as the robot extruder since they are regularly integrated with robotics. However, the printheads are also compatible with gantry based solutions. Two distinct 3D printing heads are available, the lightweight E25 pellet extruder and the high output E50 pellet extruder.

By using pellet material instead of filaments for 3D printing, operational and part cost are reduced. This solution includes everything needed for extruding thermoplastic pellet material. Including the printhead, software, electronics, material storage and material handling system.

Additionally, CEAD supplies print beds, which functions as a stable and easy to use building platform for large scale 3D printing. This page contains information on CEAD’s assortment of technology components.

Robot based solutions

A large scale 3D printing solution using robotic arms where multiple processes such as printing and milling can be combined into one cell.

am flexbot

The AM flexbot is a flexible robot based solution for large scale additive manufacturing. This versatile system provides lots of options which can be integrated to configure the system to your specific needs. This system has proven itself to be the go to system for large scale 3D printing implementations in the industry. The system is delivered and installed worldwide.

modular system

The AM Flexbot is ideal for custom solutions to fit a specific application. Siemens Sinumerik is used to directly control the Comau robot arm, meaning no robot controller is needed. This enables very accurate operation of the robot, especially in terms of position accuracy while travelling along a path. The Siemens Sinumerik can control 31 axes. Therefore your AM Flexbot can be easily extended with additional functions such as a rotary table, additional robots or other production processes such as CNC milling but also other processes.

Printing and Milling

The AM Flexbot offers the unique option to combine 3D printing and milling into one automated process. For mold making and tooling applications ideal to achieve the required surface finish. For end use parts the CNC milling functionality can ensure high tolerance mounting flanges and holes.